Freightliner

2018 New Cascadia: Tour the Cab

This five-video series looks closely at Freightliner's New Cascadia. It's not a rework or a remake of the popular Cascadia, but clean-page design. Fuel efficiency is said to be 8 percent better than the current Evolution model and a whopping 13 percent better than the base-model Cascadia. But engineers didn't stop there.

2018 New Cascadia: Exterior Walk Around

This five-video series looks closely at Freightliner's New Cascadia. It's not a rework or a remake of the popular Cascadia, but clean-page design. Fuel efficiency is said to be 8 percent better than the current Evolution model and a whopping 13 percent better than the base-model Cascadia. But engineers didn't stop there.

2018 New Cascadia: Tour the Cab

This five-video series looks closely at Freightliner's New Cascadia. It's not a rework or a remake of the popular Cascadia, but clean-page design. Fuel efficiency is said to be 8 percent better than the current Evolution model and a whopping 13 percent better than the base-model Cascadia. But engineers didn't stop there.

2018 New Cascadia: Exterior Walk Around

This five-video series looks closely at Freightliner's New Cascadia. It's not a rework or a remake of the popular Cascadia, but clean-page design. Fuel efficiency is said to be 8 percent better than the current Evolution model and a whopping 13 percent better than the base-model Cascadia. But engineers didn't stop there.

Daimler “prints” first metal truck part

STUTTGART, GERMANY - Engineers working for Daimler's European truck brand, Mercedes-Benz Trucks, have successfully used a 3D printer to create a metal thermostat cover - proving a process that could reshape the way spare metal parts are produced and distributed. With the potential of decentralizing production, 3D printing could improve parts availability, shorten delivery times, and reduce warehousing and distribution costs, the company notes. Daimler's brands in North America include Freightliner and Western Star. "With the introduction of 3D metal printing technology, Mercedes-Benz Trucks is reasserting its pioneering role among global commercial vehicle manufacturers," said Andreas Deuschle, head of marketing and operations - customer services and parts with Mercedes-Benz Trucks. "We ensure the same functionality, reliability, durability and cost-effectiveness with 3D metal parts as we do with conventionally produced parts."

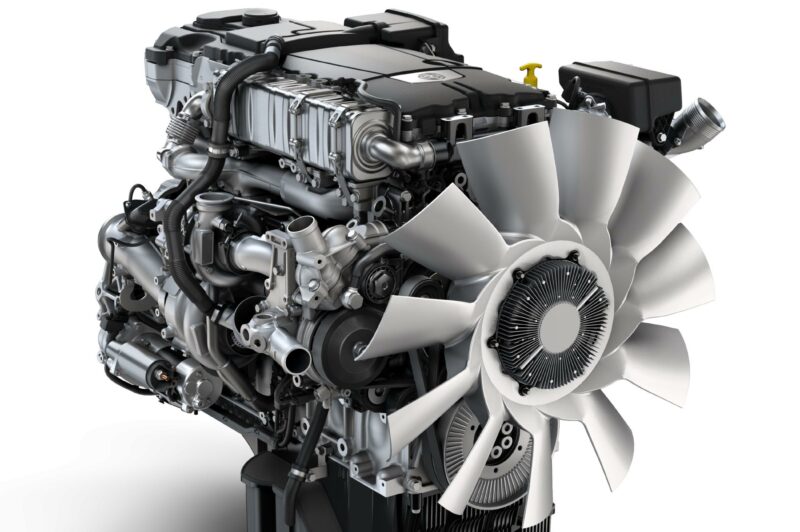

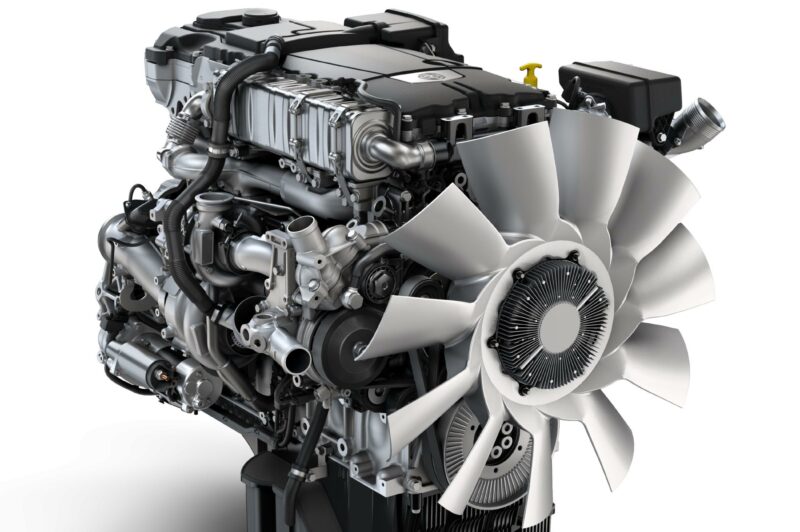

VIDEO: Fuel economy and the next-generation Cascadia

TORONTO, ON -- Today's Trucking's six-video series looks closely at Freightliner's New Cascadia. It's not a rework or a remake of the popular Cascadia, but clean-page design that improves much of what made the Cascadia popular. Fuel efficiency is said to be 8% better than the current Evolution model and a whopping 13% better than the base-model Cascadia. In this video, we dig into the Cascadia's fuel-saving potential and explores the technology that makes those savings possible.

Output shafts recalled on select Cascadias, 5700s

WASHINGTON, DC - Daimler Trucks North America will be replacing the output shafts on select 2017 Freightliner Cascadias and Western Star 5700 trucks with NFD tandem rear axles, under a recall announced by the U.S. National Highway Traffic Safety Administration.