AMTs perform, protect, and deserve some care

Automated manual transmissions (AMTs) have found a sweet spot.

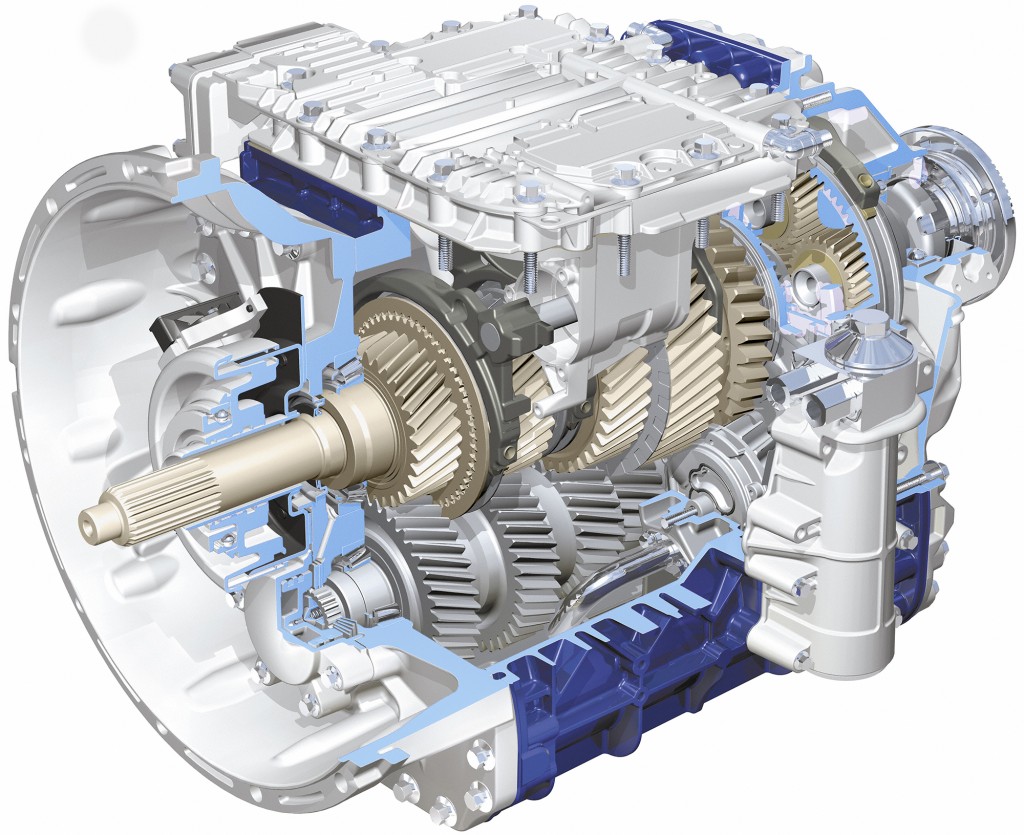

Rather than leaving drivers to find their own gears, the underlying shift logic makes the choices, drawing on inputs such as throttle position, speed, grades, and vehicle weight. Combine the transmissions with GPS locators, and predictive shifting can even become a reality as over-the-road trucks coast over hilltops and let gravity do its thing.

“When our AMT was introduced, it was stated it would make an OK driver great, and a great driver even better,” says Johan Agebrand, product marketing director at Volvo Trucks North America. “The absolute best drivers might in many cases be as good as the AMT, but the real gains are decreased driver fatigue levels by letting the computer do the shifting decision-making and letting the driver focus on the road.”

“A combination of factors [is] driving increased adoption of AMTs,” agrees Mark Saholsky, director of product management at Eaton Cummins. “The driver shortage is certainly a primary factor.”

“Once truck manufacturers were able to show how AMTs improved the truck and driving experience, fleets just needed to do their payback analysis in order to justify the increased price of the truck,” he adds. “From a performance perspective, AMTs provide better average fuel economy, longer clutch life and reduced driveline damage, and driver satisfaction features such as hill start aid, engine overspeed protection, urge to move, and predictive shifting.”

Highly integrated powertrains certainly ensure the engine and transmission work more closely together, and that’s how the better fuel economy is realized.

In the midst of it all, the grinds and clutch wear associated with manual transmissions are largely relegated to the dustbin of history. Driveline and U-joint damage associated with shock loads is reduced as well.

Clutch players

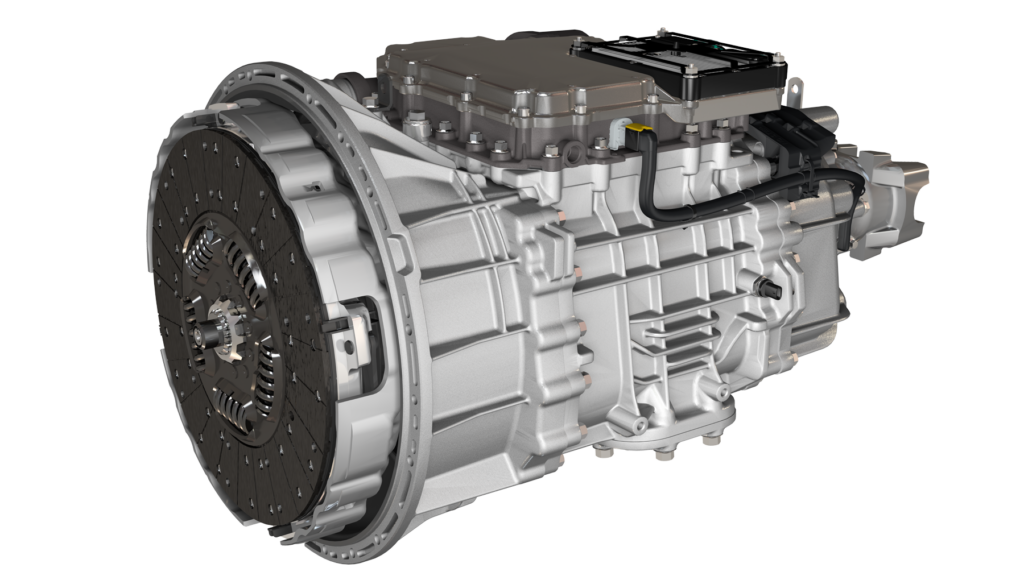

While automated manual transmissions still have a clutch, there’s no clutch pedal. The control module relies on a mechanical or pneumatic switch instead of a driver to actuate the clutch.

The efficient shifts, meanwhile, have reduced clutch failures and extended the lives of the components, says Len Copeland, a product marketing manager with Detroit products. “We hear from customers that have adopted AMTs across the board that they have reduced the [preventive maintenance] requirement of a clutch release lube that is the cause of synchro issues if not maintained.”

It’s no wonder that the systems have become the trucking industry’s transmission of choice. These days, manual transmissions are the rarity in new Class 8 trucks – at least, when it comes to on-highway models.

“There are almost no unique considerations for AMTs,” Copeland says. “All transmissions require the fluid to be changed at regular intervals. Refer to your manual for the OEM-recommended change interval. Air system maintenance should be a priority regardless of the transmission type. Air tanks should be drained daily to mitigate issues.”

But like any other truck component, AMTs also present some unique maintenance requirements.

Saholsky points to the data links as an example. “When not functioning properly, data links can cause undesirable vehicle launches and shifting issues after launch,” he explains. “Many new vehicles have an extremely high bus load on the data link, which can cause error messages if any of the electronic control units are improperly functioning or if the physical wiring of the data link has been compromised.”

Newer vehicles have incorporated 250K and 500K baud rate data links to reduce some issues, he notes.

“With the electronic control of the AMT, we are better able to monitor for potential maintenance,” adds Agebrand. One example is the self-adjusting clutch, he says. “Once it’s installed and calibrated, the transmission ECU keeps track of the wear and will alert the driver when the clutch is due for replacement. There is no service of the clutch or related components needed on a regular basis.”

There’s another benefit to an AMT’s underlying sensors. The fault codes will guide more maintenance activities. Freightliner’s Cascadia Maintenance System, for example, automatically adjusts fluid change intervals based on operating conditions and driving style.

“One unique feature of AMTs is clutch overheating,” Copeland adds. “Drivers should be aware of clutch heat — an overheated clutch has a burnt smell — both for AMTs and manual transmissions.” The DT12 transmissions include a clutch temperature sensor to monitor that very issue. “If the transmission fails to shift into a gear smoothly when driving an AMT, that is an indicator of a clutch problem.”

Power and dry air

The important inputs are not limited to data alone, either. The AMTs also depend on sound electrical connections.

“Battery maintenance is crucial for electrically shifted AMTs,” Saholsky says. Fleets and owner-operators who adopt the equipment could see battery replacement cycles drop to 12-18-month intervals, for example. “Beyond battery monitoring and maintenance, fleets should also check the electrical system on a regular basis – looking for things like corrosion, wire chafing, and loose connections.”

Inspecting and maintaining air dryers becomes equally as important when maintaining the pneumatically shifted systems.

“Many fleets do not replace the desiccant cartridge during routine maintenance. Some wait until the dryer fails,” Saholsky says. “When that happens, the air system has already been ingested with moisture, which can affect AMT performance. Moisture in the system can result in harsh shifting or even a lost of shifting completely.”

Lubrication intervals, though, tend to be similar for AMTs and their manual counterparts. But there is a difference in the type of lubricants used.

Even if an oil has the same weight as the recommended lube, it might not incorporate the right additives, Copeland warns.

But the spec’ing considerations when selecting an AMT will seem familiar.

“Different approaches toward spec’ing trucks are not necessary,” Agebrand says, noting that the programming options are matched to engine spec’s and optional features during the spec’ing process.

“If your vehicle is being run [over the road], make sure the AMT is spec’d for the road speeds it will encounter. Likewise, if you are a heavy haul application, make sure the transmission selected is designed to handle the weights and operating conditions it will encounter,” Copeland says.

“Unless you are looking at some very heavy-haul situations where a shorter step between gears is needed, and an 18-speed would be more suitable, the AMT will cover most applications,” Agebrand adds.

Admittedly, AMTs are still not for everyone. Manual transmissions still tend to be a favored option among heavy haulers or severe service operators. But Eaton expects to see AMTs becoming more prevalent as emission standards tighten, requiring evermore tightly integrated engines and transmissions.

“That’s something you can’t do with a manual transmission,” Saholsky says.

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.

Anyone who’s been drivin a while and had the opprtunity to drive an automatic and a stick , I think most experienced and able bodied drivers would still prefer the stick ove an automatic. I know I do!!

I laughed at 500k baud, no wonder auto/truck makers are hurting for computer chips, that is 1990’s technology. When are they going to step into the 21st century? Data speeds should be several Gbps not 500k baud. That only is .000006 Gbps