Webasto Charging Systems offering NACS connector option

Webasto Charging Systems is offering a North American Charging Standard (NACS) connector option for its charging systems.

The company says it had already developed a fully functioning mobile cordset sample with the NACS connector, even before major automakers standardized NACS.

“We are committed to delivering cutting-edge charging solutions that meet the evolving needs of the U.S. market,” said Michael J. Bauer, president and chairman of Webasto Charging Systems. “Integrating NACS connector options throughout our product portfolio demonstrates our dedication to driving the adoption of electric mobility and enabling a sustainable future.”

“The NACS connector solution has been in active development, well ahead of recent industry announcements. This showcases our commitment to delivering advanced charging solutions that align with industry standards and requirements,” added Michael Schoenberger, vice-president — research and development.

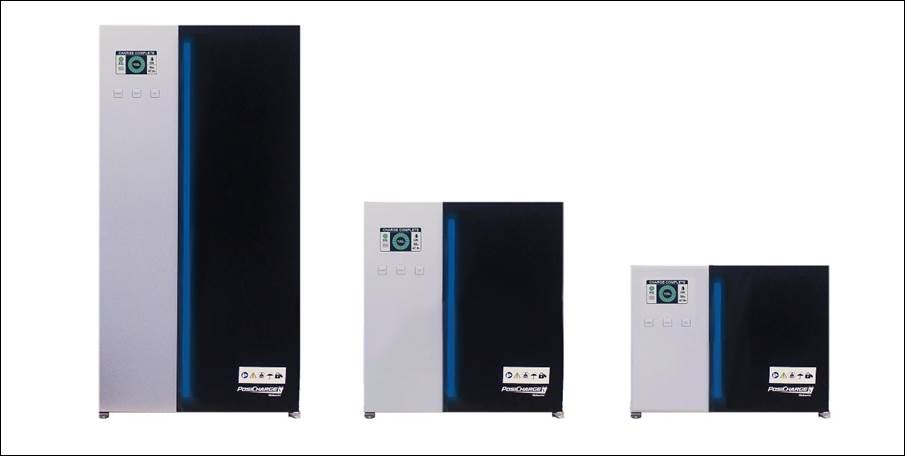

Webasto Charging Systems in North America offers the Webasto Go mobile charger, the connected TurboConnect wallbox – ideal for fleets – and the cost-efficient TurboDX 2.0 plug-in charger. All will soon be offered with the NACS connector option, the company says.

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.