Detroit Gen 6 engine targets EPA27’s ultra-low NOx requirements with familiar design

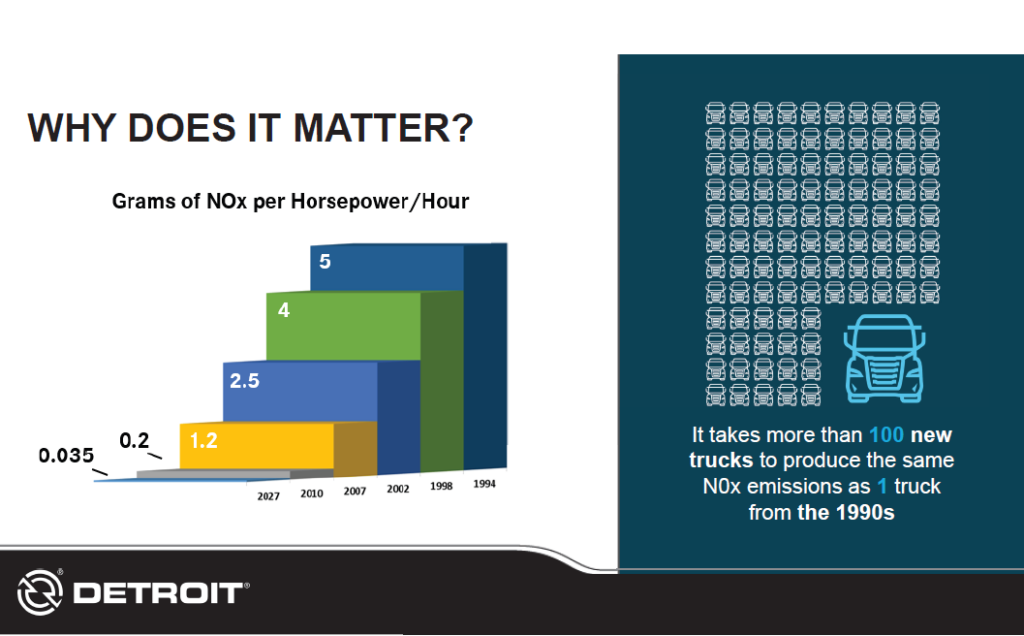

A lot has changed in seven years, when Daimler Truck North America (DTNA) began working on its sixth-generation Detroit engine, designed to meet the EPA27 ultra-low NOx limit of 0.035 grams per hp/hr.

A new administration in the United States ushered in a vastly different approach to emissions regulations, but Daimler has remained steadfast in its approach to the new design. It wanted to come up with an engine that brought value to the end users, regardless of regulations, and wasn’t simply a means to meet regulatory requirements. And in doing so, it focused on simplicity, familiarity and reliability in coming up with the Gen 6 engine.

While the EPA27 emissions rules have been placed under review by the current administration, engine makers didn’t have the luxury of sitting on their hands and waiting for potential changes.

Customer first, regulation second

“This has been in development for almost seven years,” Greg Braziunas, head of powertrain engineering with DTNA said during a launch event earlier this week. “Even before we knew the final emissions regulations, we always had in mind that we wanted to improve efficiency. That’s where we started, with the customer focus in mind, to really improve that value proposition for them. As the EPA Clean Truck Plan passed, we incorporated some of those other requirements.”

The NOx reduction is significant, from 2 grams hp/hr today to 0.035 in 2027. While the EPA27 regulation is technically still under review, the EPA has given the OEMs guidance that the NOx limit will remain intact. Other aspects of the regulation that could yet be tweaked relate to the extended warranty requirements on the aftertreatment system, an element that was the greatest source of additional costs.

Daimler feels the Detroit Gen 6 is ready for the regulation as it’s written today, as well as any last-minute changes.

“We feel very confident in our path to 0.035,” said David Carson, senior vice president, sales and marketing with DTNA. “We don’t have an endless amount of time to have an engine available for customers in 2027.”

A simple, familiar approach

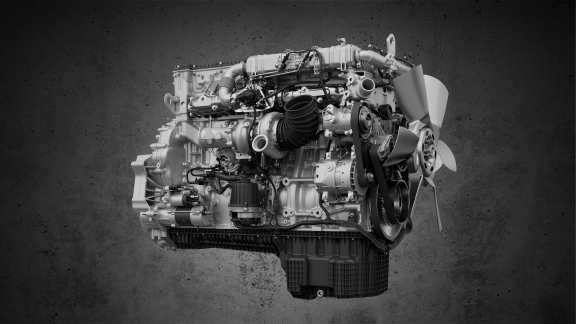

To reduce NOx emissions to such microscopic levels isn’t an easy engineering feat. And Detroit engineers wanted the transition to be seamless for customers. To that end, they designed an engine that would seem familiar to fleets.

The one-box aftertreatment system has been retained but slightly enlarged to accommodate a pre-SCR (selective catalytic reduction) system, explained Braziunas.

“It should look quite familiar to you,” he said when revealing the engine and one-box system for the first time at the company’s Detroit headquarters and engine plant. “It’s a larger box but this is virtually the same unit we’re putting on our trucks today. There have been small tweaks to the substrates on the inside, but it has the exact same outer shell.”

The pre-SCR system sits atop the existing unit. This provides NOx controls further upstream, converting NOx earlier in the drive cycle, which is particularly beneficial during engine warm-up. (The EPA27 regs introduce new requirements for emissions control at idle).

Braziunas said the company has perfected its SCR system over the past 15 years and wanted to retain as much of that system as possible.

“We’re taking the same perfected technology and using it in the pre-SCR system,” he said. “In all our applications, we have room on the vehicle where we can place this. In vocational applications, we still have the full clean back-of-cab, which is really important.”

Aftertreatment the ‘star’

Trucking companies have a love/hate relationship with exhaust aftertreatment. It was a rocky start when the EPA began cracking down on NOx emissions in 2010, ushering in the rushed adoption of SCR and related headaches. Those industry-wide frustrations have been put to rest over the years, and the aftertreatment system on the Gen 6 engine “is the star of the show in a lot of ways.”

That, according to Steve Collins, director of Detroit field sales engineering.

“It’s a really simple, low-complexity design with no additional space claim,” he said of the one-box unit. But, he added, Detroit’s ability to achieve 0.035 g/hp/hr with only minor changes to the aftertreatment design “wouldn’t be possible if we didn’t have an extremely efficient engine upstream.”

Modifications to the base engine include a new oil-lubricated fuel pump, which eliminated the need for amplified injectors and enabled a simpler high-pressure common rail fuel system design.

In addition to providing improved lubricity, the new oil-lubricated pump allowed engineers to improve robustness.

“Customers can’t always control the quality of the fuel they have access to,” Collins said of the previous fuel-lubricated system. “Having a really robust fuel system adds efficiencies for the customers.”

The air management system was also fine-tuned and the camshaft timing was adjusted to lessen the demand during compression strokes, reducing friction and optimizing combustion efficiency.

The new pump design not only reduces oil consumption but also lessens the workload required of the pump. Heat is a key ingredient to converting NOx, and any rise in heat typically sees a corresponding increase in diesel exhaust fluid (DEF) consumption.

Detroit engineers were able to claw back some of that increased DEF consumption through new efficiencies built into the Gen 6.

A reduction in friction allows more power to transfer to the wheel ends, where it’s needed to propel the vehicle. This enabled the designers to introduce three new power ratings, two on the DD15 and one on the DD13. (The DD16 is also being updated to comply with EPA27, but won’t be offered until 2028. Until then, Daimler is able to redeem emissions credits in order to continue selling the Gen 5 DD16).

The DD13 will be available with 505 hp/1,750 lb.-ft. rating while the DD15 adds 425 hp/1,900 lb.-ft. and 455 hp/1,900 lb.-ft. variants.

“The new ratings enable further downspeeding,” said Collins. “More fuel savings without affecting performance.”

The asymmetric turbo has been retained but optimized, with a fuel-saving ball-bearing design now standard across the entire line. Maintenance intervals and diesel particulate filter design on the Gen 6 are unchanged from the previous engine.

A new engine oil category — dubbed FB-4 — is being designed by the American Petroleum Institute to optimize compatibility with the EPA27 NOx requirements. Daimler is still undecided on whether that will be the factory fill come Jan. 1, 2027. The decision may hinge on the availability of FB-4 at the time of launch. However, the company notes it was the first engine maker to make FA-4 – the current low-viscosity oil category – a factory fill.

The new engine will be paired with the Gen 5 Freightliner Cascadia, introduced last year but replacing the previous version completely in January.

“There will be pricing consequences, but based on the path we took, we believe that it’s not a number that was quoted early by some of our competitors, which was a massive price increase.”

David Carson, DTNA

Buy now or buy later?

Carson said there are no signs yet of a pre-buy to get ahead of EPA27-related pricing increases.

“At the moment, nobody is buying just because they think there will be constraints or other consequences in 2027,” he said. “They’re not comfortable enough in overall business conditions.”

While there has yet to be any details shared on pricing of the new engine, Carson said he anticipates any increase will be lower than some of the figures that have been publicly floated. (This desk has seen predictions ranging from $8,000 to $30,000).

“There will be pricing consequences, but based on the path we took, we believe that it’s not a number that was quoted early by some of our competitors, which was a massive price increase,” Carson said.

Daimler will begin pre-production as soon as March so customers can gain some comfort with the new design before the full changeover occurs when the calendar flips to 2027.

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.