DIY Maintenance for Owner-Operators: Chassis inspection

Over the past decade we’ve seen trucks inundated with electronics. Parts and components that were once happily mechanical, now have all kinds of wires dangling from them.

That means you probably can’t fix them yourself. Just march off to the parts department, drop three times what you think the part should be worth, bolt it on, plug it in and you’re good to go. Labor savings is a virtue.

But if you’re itching to get a little grease under those fingernails, fear not: There is plenty of stuff between and below the frame rails to keep you busy for an hour or two every couple of weeks.

There are lots of moving parts down there making metal-to-metal contact. That means they need lubrication and periodic inspection for wear, and occasionally, retightening or retorquing of certain vital parts. You needn’t be a mechanic for this sort of job. You just need a keen eye and a torque wrench.

Since you’ll be working under the truck, be sure to set the parking brakes and chock the wheels. Also, keep the keys in your pocket or put them away safely where someone else can’t easily grab them and unknowingly start the truck and drive away.

Frame and fasteners

Inspect the visible sections of the frame for obvious signs of cracks or deformations, particularly in the lower flange. Cracks can appear like hairline cracks in the frame paint.

Cracks in the paint are not uncommon, but if you see any rust around such a crack, it can indicate a damaged frame component. You are more likely to find such cracks on older equipment, and they can be hard to spot. Check both the inside and outside of the frame rails.

Fasteners used to secure other components to the frame are often bolted on, and these bolts can loosen with repeated flexing of the frame and crossmembers. Huck bolts almost never loosen, but they have been known to break.

Look for signs of movement between two usually mated surfaces. Telltale signs include broken or missing paint on the fastener itself or the frame area. If a bolt is loose enough, it may vibrate or rattle against the mating surface leaving shiny metal exposed that looks like it’s been sanded or buffed. If you see bare metal under a nut or a washer, it will need to be retightened or retorqued.

Mounting bolts should be retorqued to the factory specifications (your dealer can supply that information) and any replacement bolts must be the same size and grade as the original.

Pay particular attention to hardware used in load-bearing positions such as suspension mounts, fifth wheel mounts, and axle U-bolts.

Suspensions

Suspensions, as robust as they are, support the entire truck and are exposed to some tough operating environments. Regular visual inspections are essential. Repairs are usually best left to the experts.

Air suspensions: Inspect bushings and rubber parts for chafing, wear, and core displacement. Bushings typically are concealed within brackets or other mounting structures making them difficult to see. Bushing wear can also be felt by degradation in the truck’s ride characteristics.

Inspect the shock absorbers for proper mounting and overall integrity at least weekly. A properly functioning shock will be warm to the touch after driving. A leaking shock is not an out-of-service issue, but it can lead to reduced service life and/or increased tire wear and ride quality issues. Misting, or an oily/dusty film in the shock body is no cause for concern.

Inspect the air springs to ensure nothing is rubbing against it which could lead to damage. Periodically check for road gravel or other abrasive debris between the cell and the piston and the bead plates. Removing the debris will help to prevent air cell abrasion and premature failure.

Leaf spring suspensions: All fasteners should be rechecked for proper torque, including the axle connection U-bolts, center equalizer bolts, the torque arms (both fixed and adjustable), and the spring retainer hold-down bolts. You can find fastener torque values in suspension maintenance manuals, or your dealer can provide the information.

Inspect the spring pack for any separated leaves (you’ll see a gap between two pieces of the spring). If the spring is cracked but hasn’t separated, you often see a dark line on the edge of the spring leaf (it’s really a crack) with fresh looking rust around it.

Anywhere you have metal-to-metal contact and movement, you have the possibility of wear related damage. Look closely at the inside of the spring hangers where the top leaf of the spring pack moves freely. You’re not off the hook with the suspension and the fasteners. There’s lots more down below that deserves a little attention. Here’s what to look for:

Steering components

Repairs to any steering-related problem are best left to experts in most cases. Properly functioning steering components are vital to the safety of the truck.

Inspect all the linkages for looseness or slack between the joined parts, including the steering gear output shaft(s), pitman arm, drag link, and steering arms and tie-rods. If you can move them by hand, they need to be repaired.

Check for cracked or loose or missing clamps and ensure all the appropriate hardware and fasteners are present and tight.

Check the input and output shafts of the steering gear and the U-joints in the steering column for free play in the gears (free movement).

At the steering wheel, this is free movement of the wheel without a corresponding movement of the wheels. CVSA allows an extraordinary four or five inches of free rotation of the steering before placing the truck out of service. If you notice anything more than about two inches of steering wheel lash, it’s time to visit the repair shop.

Cable and hose tiedown points

Truck makers thread wiring harnesses and air lines, etc., through the frame and crossmembers, and secure them at various points with cable ties or clamps. If these tiedown points are too tight, they can crimp hoses. If they are too loose, cables and hoses can chafe and rub through.

Carefully inspect these tiedown points as well as the unsupported run of the cable bundle for signs of rubbing against metal or other hoses and cables. Be on the lookout for spots where cable or hoses are rubbing against some other part of the truck such as a frame rail or an air tank.

With rubber hoses, look for flat spots in the hose or signs of the interior cords of the hose showing. Those are almost always out-of-service items.

Look for bare wires or exposed contacts, especially any with signs of greenish powdery build up around the connection. That’s a sign of corrosion and a connector that’s likely to fail sooner rather than later.

Fifth wheel inspection

Roadside inspectors pay close attention to fifth wheels. It must be securely attached to the tractor and capable of towing the trailer with no possibility of the two units inadvertently uncoupling.

Ensure all the fifth wheel mounting hardware is in good condition with no cracks or broken welds in the mounting plates or pivot brackets. If any of the fasteners are missing, replace them with the proper size and grade of bolt.

The top plate of the fifth wheel should be free of cracks or deformations and be kept well lubricated.

Roadside inspectors check for slack or movement on the pivot brackets and the kingpin locks, too. When coupled to a trailer, check for fore and aft movement in the locking mechanism and the pivot bushings. If there’s any slack in the fifth wheel, get it repaired as soon as possible.

Inspect the underside of the fifth wheel for excess grease build-up. The dried-out, lumpy, globby grease can affect the function of the locking mechanism. It’s also viewed by inspectors as an environmental concern.

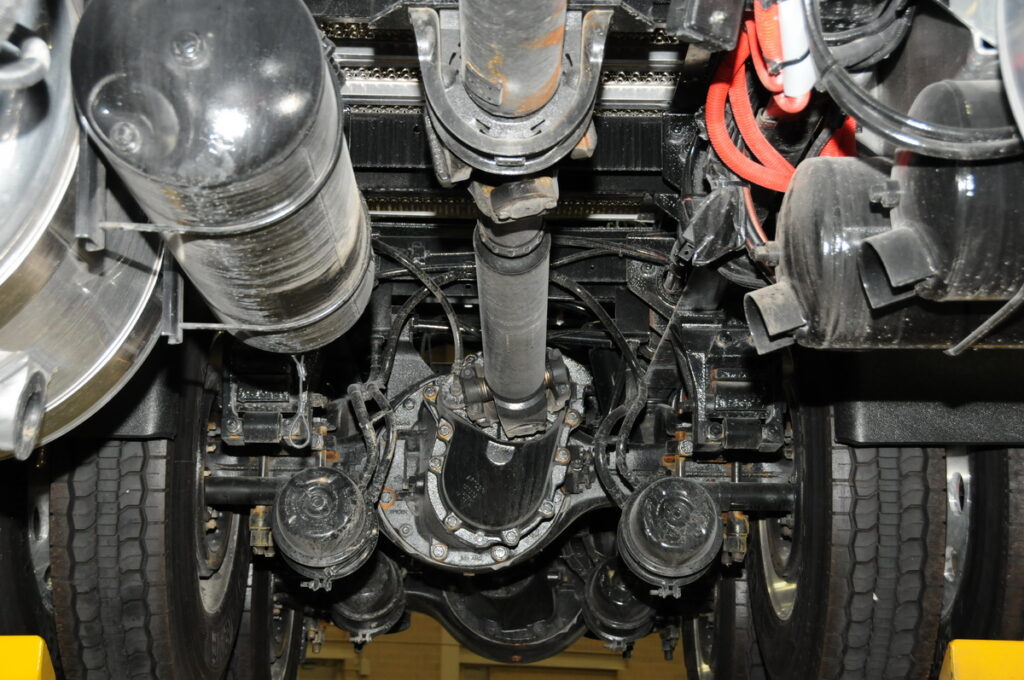

Driveshaft and driveline

The driveline is obviously critical to the operation of the truck, and it’s a part that’s under constant load. They need to be properly lubricated and free of any signs of damage or degradation.

Check the driveshaft tubes for cracks or broken welds along the length of the shaft and especially where it attaches to the yoke. Look for signs of twisting too.

Check the hanger bearings along the length of the driveshaft. These are usually lubed for life but check for leaks around the seals and signs of rust around the bearing. Ensure the mounting bolts are present and tight, and there are no cracks in the hanger assembly.

Check for cracks in the yokes and grease leaking from around the bearing caps in the U-joint yokes. Many U-joint yokes are now permanently lubricated but check for the presence of a grease fitting and grease it regularly if required.

Check the yokes and U-joint assemblies for signs of movement. Using just hand pressure, try to move the U-joint up and down and side to side. It should not move at all. CVSA will place out-of-service any u-joint with movement greater than half an inch.

Frame-mounted equipment

Inspect the exhaust system for mounting integrity and leaks. Carefully inspect lengths of flex pipe and connector clamps for corrosion or damage. Any leak under or forward of the cab or sleeper is considered an OOS condition. Where applicable, check the sensor wires and DEF tank hoses for corrosion and/or damage.

Check the fuel tank mounts and straps for loose fasteners and be sure the whole mounting assembly is in good condition. Check around the tank draw and return fittings for leaks or loose connections and inspect fuel hoses for signs of rubbing, chafing or kinks. The same goes for the air tanks.

Examine auxiliary components such as air dryers and APUs for mounting integrity, damage and hose and cable connections.

Lubrication

Before you come out from under the truck, you have one last chore to complete: grease the thing. Anywhere you see a grease fitting, sometimes called a zerk, you have to apply some grease.

If the fitting will not take any grease, replace it. And, check the component is properly lubricated. If the fitting won’t take grease, it may have been some time since it last saw fresh grease.

Check your truck’s lubricant recommendations in the owner’s manual. In most cases, a good quality high-pressure (HP) all-purpose grease will be fine for the purpose.

When applying grease, squeeze the handle of the grease gun firmly but slowly.

The parts are properly greased when you see a bit of fresh greased ooze out from the between the moving parts.

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.