Technology for sale

MISSISSAUGA, Ont. — Polaris Transportation has prided itself on its technological innovation, and has now spun out a tech company through which it will market some of its homebuilt technologies.

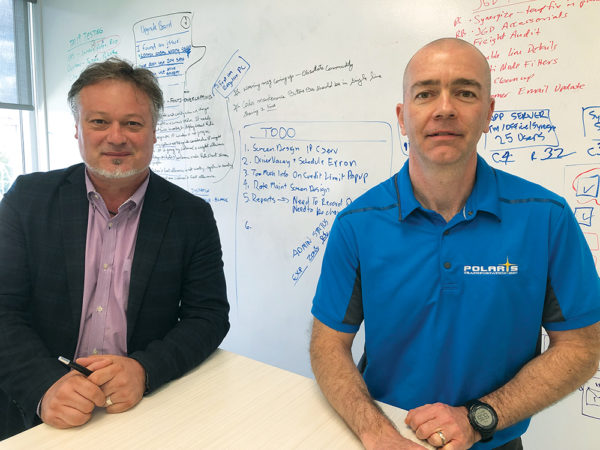

NorthStar Digital Solutions, operated out of Polaris’ headquarters with eight dedicated staff, offers custom-built technologies that will help fleets digitize their businesses and benefit from emerging technologies. During a recent visit to Polaris, Dave Brajkovich, chief technical officer, and Dave Cox, president of Polaris, told Truck News why the company is looking to share with its competitors some of the proprietary competitive advantages it has built in-house.

“Our ultimate goal is to digitize our supply chain,” said Cox.

But rather than buying off-the-shelf products to do so, Polaris has invested in developing its own technologies. It brought in Brajkovich, who has a tech background and was serving on the company’s board, and began building its own customized platforms. It also saw an opportunity to sell these systems to other carriers, and so NorthStar Digital Solutions was born. Cox describes NorthStar as a “digital factory.” Polaris is currently its main customer, but it’s looking to branch out within the transportation industry, and beyond.

The focus will be robotic processing, automation, artificial intelligence, and distributed ledgers (aka blockchain).

Polaris handles 300,000 cross-border shipments per year, and Cox envisioned digitizing that supply chain and reducing monotonous labor for his staff.

Rather than processing paperwork, he wants them focused on solving exceptions. Brajkovich said NorthStar Digital has built bots to handle “straight-through” processing, freeing up staff to focus on exceptions. He said the bots can handle up to 80% of the straight-through processing at Polaris.

“I want to have people who can use the creative sides of their brains to find solutions for internal customers or external customers,” said Cox. “I want them to be able to watch gauges and pull levers when required.”

Polaris was the first to implement NorthStar Digital’s technologies, and it bore the cost of developing them. One of the biggest advantages so far, said Brajkovich, is a reduction in errors. He claimed bots are less prone to errors and they also identify and flag bad data.

“The data that’s collected is very clean,” he said. “They won’t process things in a dirty state…If there are three accounts for the same company, the bot will see there’s three and say ‘These two are irrelevant, let’s clean that up.’ They cleanse the data for more accurate reporting.”

Polaris now sees data reports hourly, which Cox and Brajkovich said is more accurate than in the past. Order entry is one of the first functions to have been digitized. Next to come, is a distributed ledger, widely known as blockchain.

NorthStar Digital is building a blockchain platform it will offer to customers on a click charge or subscription fee model.

“We provide the tool and the platform,” Brajkovich said. This will bring to users benefits such as smart contracts – including the ability to receive payment the moment the delivery is made, and to reduce disputes with shippers due to the centralized nature of the contract.

Next up, NorthStar plans to offer Internet of Things products. It’s looking to add GPS tracking to individual shipments, which can be disposed of when the delivery is completed.

“We are working with vendors right now to get to the point where it becomes throw-away GPS tracking and at the end of life, the battery dies and is disposable,” Brajkovich said. “It doesn’t need to be sent back, and from a last-mile perspective, that becomes complicated if you have to send the tracking units back into the fold.”

NorthStar is looking beyond the transportation industry for customers, as it feels its technologies can be adapted to other industries as well. Ultimately, said Cox, the technology allows for scalability. Automating workflow allows customers to more easily scale up in busy times without adding more staff, and down in slower times, by simply reducing the number of bots handling certain processes.

A customer looking to implement its currently available digitization technologies is looking at about a three-month implementation period, at which time the company says about 60-80% of straight-through processing can be automated, and error rates significantly reduced. It is looking to reduce that implementation period down to two months. Various pricing models are offered.

The company is actively demonstrating its technologies to interested prospective customers. Cox said the NorthStar concept has been in the works for about two years, and “took Polaris into the next world.”

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.