Eaton expands clutch portfolio

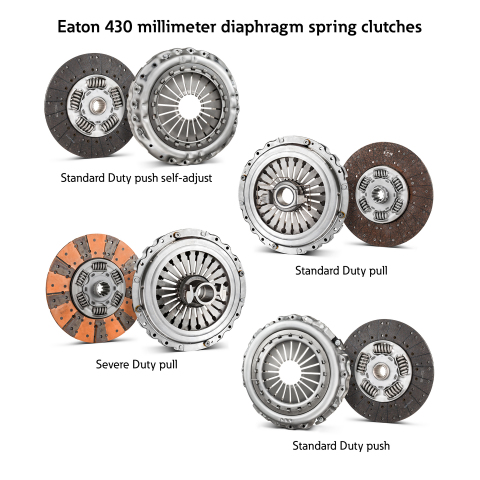

Eaton has expanded its 430-millimeter diaphragm spring clutch portfolio for heavy-duty commercial vehicles, supporting downsized and downspeeding engines.

They come in a variety of actuation styles and damper sizes.

The newer engines produce peak torque at lower RPMs, which can also increase torsional vibration, Eaton explains. Its 285-millimeter diameter damper clutches are designed to reduce those vibrations and feature the first application of Eaton’s Soft Stop technology in a heavy-duty application.

Soft stops reduce the stress on the damper springs during potential over-torque events.

Heavy-duty diesel engines traditionally use a 232-millimeter or 254-millimeter diameter damper, which keep engine vibrations from traveling through the clutch, into the transmission, down the driveshaft, and into the axles.

A new push self-adjust Extreme Duty model clutch is also available in 254-millimeter and 285-millimeter damper sizes with 1,950 ft-lb. torque ratings. Alloy components feature a higher thermal capacity and an optimized pressure plate mass in the name of durability and low-speed maneuverability, Eaton says.

The main damper springs have been upgraded for improved noise, vibration and harshness characteristics.

Extreme Duty clutches use a new organic facing, more robust pilot bearing, and are designed for more frequent starts and stops found in on/off-highway applications. And they provide 63% more actuations over standard-temperature versions, minimizing the number of “clutch abuse” warnings before intervention, which allows for 50 percent more launches, Eaton adds.

Standard-duty models previously available in a 232-millimeter damper and 1,585 ft-lb torque rating also are now available in a 254-millimeter damper with a 1,950 ft-lb rating and a 285-millimeter damper with a 2,050 ft-lb rating.

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.