Clean energy initiatives will require future fluids

BRYAN, Texas – Jason Brown, Shell’s global technology manager for heavy-duty diesel engine oil, knows electric vehicles are coming. But that doesn’t seem to faze one of the world’s largest producers of fuels and lubricants.

“We’re definitely going to have electric vehicles. It’s going to be there,” he said during a media briefing at the Texas A&M Transportation Institute.

These same vehicles, though, will have lubrication needs of their own.

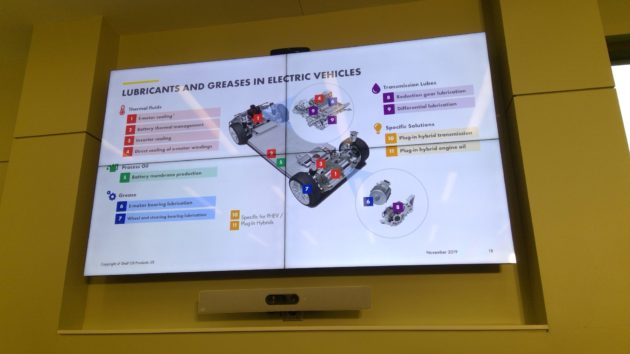

Thermal fluids will be needed to cool electric motors, inverters, and motor windings, and to support battery thermal management. Specialized process oils will be needed to protect battery membranes, too. There will be greases to lubricate electric motor, wheel and steering bearings, and the transmission lubes for reduction gears and differentials.

Plug-in hybrid vehicles will also require specific solutions when it comes to transmissions and engine oil. Higher stresses on internal combustion engines within such systems will include frequent stop-starts, while sustained electric vehicle operation will affect fuel dilution, water content, and emulsion formation, Brown says.

Electric vehicles require lower oil volumes, but also introduce higher power outputs, more compact designs, higher complexity, different operating conditions, higher thermal stresses, and need to protect against wear at lower temperatures.

There are also conductivity issues to consider when copper wires and fluids mix. “Not everything is going to be coated,” Brown said. And transmissions in electric vehicles will turn at higher rates, requiring improved controls against foam.

A diverse energy mix

As important as electrification will be, Shell believes the battle against CO2 emissions will also require more than one energy source.

“You’re going to need a much more diverse mix of energy going forward,” Brown said.

Oil and coal are still abundant and practical fuel sources, he observed, referring to the infrastructure that’s already in place to transform them into energy. Even electric vehicles need infrastructure support because today’s grid couldn’t handle everyone plugging into an electric car. A grid capable of doing that is still expected to be decades away.

“That building is going to take time,” he said, “and it’s going to take money.”

Shell itself is taking a broad-based approach to energy. It’s building retail sites for hydrogen, and investing in conventional and advanced biofuels alike. In terms of electrification it is investing in slow and fast-charging stations for electric vehicles, while also supplying compressed natural gas (CNG) and liquefied natural gas (LNG). It’s one of the pioneers in gas-to-liquid (GTL) fuel as well as nature-based solutions.

None of them will be a “silver bullet,” Brown stressed, referring to the drive to reduce CO2 emissions. “The best way to do that is to invest in all of them.”

The approaches might even vary by region.

“Natural gas is pretty available globally,” he said as an example.

Existing resources could offer more than 230 years of the fuel at current production rates, Shell projects. And gas-fired power plants emit about half the carbon dioxide of their coal-fired counterparts.

Boosting fuel economy

Ongoing efforts to enhance the fuel economy of internal combustion engines continues as well.

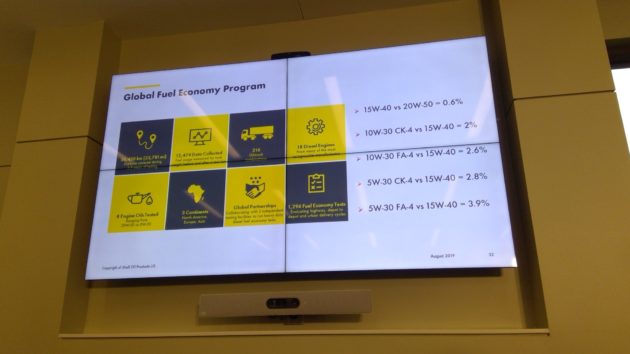

Over the last 2-1/2 years, Shell has compared eight engine oils ranging from 20W-50 to 0W-20, in markets around the world. And it has seen differences in the different oil weights through evaluations in on-highway, depot-to-depot, and urban delivery cycles.

When compared to 15W-40 oils, a 10W-30 CK-4 bettered fuel economy by 2%, while the 10W-30 FA-4 was 2.6% better, the 5W-30 CK-4 was 2.8% better, and a 5W-30 FA-4 oil bettered the fuel economy by 3.9%.

Major OEMs already recommend a 10W-30 CK-4 oil for their engines, Brown said. Trucks around the world are collectively leaving billions of dollars in fuel savings on the table if they don’t use it.

There’s a direct link between fuel economy and environmental targets as well. The broad-based shift from higher-viscosity oils to a 10W-30 CK-4 could save 2.1 billion kilograms of carbon dioxide. A 5W-30 FA-4 oil could save 3.5 billion kilograms.

Reaching for the Starship

In pushing future limits, Shell continues to move forward with demonstrations like its Starship Initiative. That concept vehicle featured enhanced aerodynamics, low-viscosity lubricants, and better energy recovery systems.

Hotel loads were powered with a roof-mounted solar panels, while 6×2 axle configurations reduce weight and friction. Low rolling resistance wide-base tires and automatic inflation systems improved rolling resistance in their own right. And an active grille cooling system closed when cooling was not needed, to improve air flow.

It hauled 39,900 lb. of reef material between California and Florida.

The Starship averaged 8.94 mpg compared to the U.S. average of 6.4 mpg, but more important is that it delivered 178 ton-miles per gallon compared to a typical 72 ton miles per gallon.

“We’re going to do more. We think there’s more to be done with this truck. We are going to make some improvements,” Brown said, referring to another demonstration run planned in 2020. “We still think there’s some story for the Starship Initiative.”

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.