Feds explore emissions, trailer upgrades

Many day-to-day trucking regulations are anchored in provincial rules, but the federal government is in the midst of several initiatives that apply to emissions, trailer skirts, long combination vehicles, and tanks that haul dangerous goods.

Details about the programs emerged Oct. 20 during a regulatory update hosted by the Canadian Transportation Equipment Association (CTEA). Here are some of the highlights:

Emissions standards

Plans to introduce the first greenhouse gas (GHG) standards that apply to trailers have been put on hold until at least May 3, 2022, in the face of challenges to U.S. regulatory changes.

“The matter is still before the court,” said Julie Deschatelets of the transportation division in Environment and Climate Change Canada’s energy and transportation directorate.

But there are other emissions-related updates in the works. Next year, new GHG standards are expected to emerge for Model Year 2027-and-later vehicles, and by July 2024 there should be GHG standards that apply for Model Year 2030 and beyond.

While Canadian emissions rules generally mirror those established in the U.S., the limits may not come from the U.S. Environmental Protection Agency (EPA) alone, either.

Canada recently strengthened its climate plan to align with the most stringent targets in North America – whether at a federal or state level – for vehicles built 2025 and later, Deschatelets said. And California has established several standards that are stricter than those developed federally.

Multi-trailer stability

Multi-trailer configurations like Long Combination Vehicles (LCVs) improve productivity and lower overall emissions. And there are an increasing number of such vehicles on the road, said Gordon Poole, senior project manager with the National Research Council.

But such configurations are not without their challenges when it comes to stability at high speeds and maneuverability at low speeds. So federal researchers are looking for ways to improve the stability through trailer differential braking, active trailer steering, analyzed routes, and a focus on wind gusts.

The data collected around wind gusts will include physical measurements and calculations alike, all of which will be combined with machine learning with the hope of improving the electronic stability controls for tractors and multi-vehicle trailer combinations.

The active trailer differential braking and steering systems will look to improve directional and roll stability as well as maneuverability, Poole said. Those could see additional trailer sensors and algorithms to better control the vehicles overall.

Lab tests are already being developed, while road and track tests are also on the horizon, he said. Work on the differential braking began this year, while the look at mitigating wind gusts and analyzing routes begins next year.

Predictive route tools could help route planners and drivers better understand the risks based on everything from vehicle configurations, to real-time weather conditions, he explained. Even a driver’s background could be considered.

Side skirts and guards

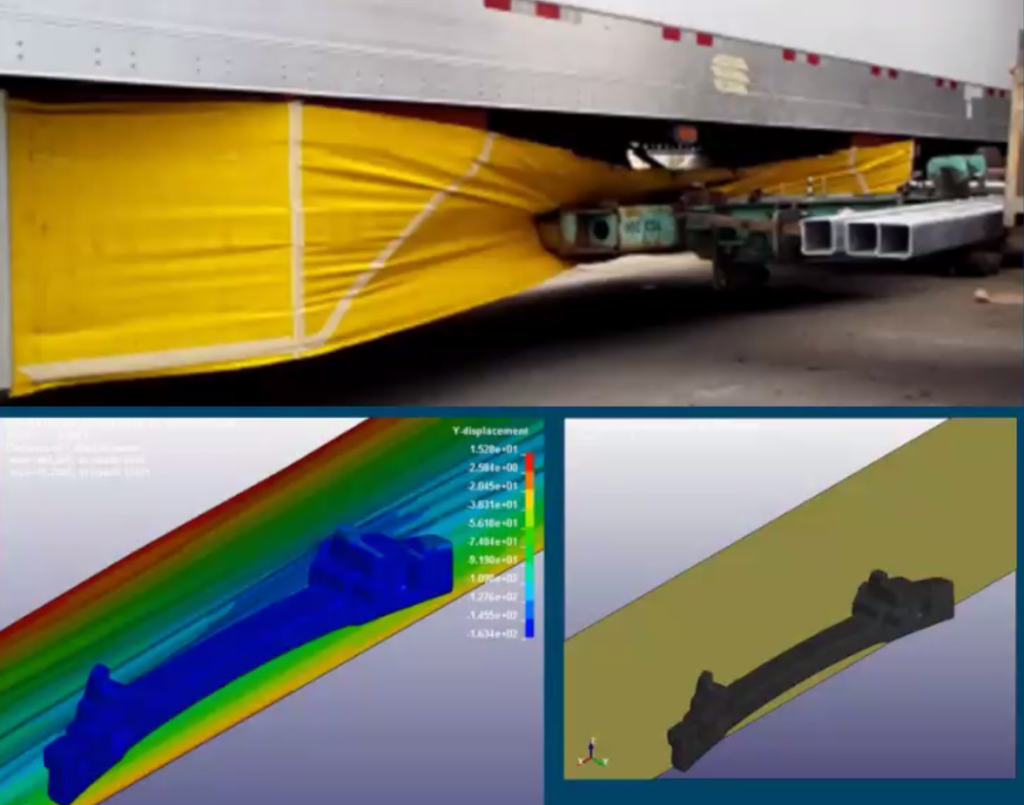

Lateral underride protection – or side guards – have been discussed on and off for years, but there is a renewed focus on the role that side skirts could play, Poole said.

Most side skirts designed to reduce aerodynamic drag are not meant to offer added protection during a crash, but side underride guards have shown the can reduce injury risks, he added.

The National Research Council is exploring whether they could be regulated much like the underride guards at the back of a trailer.

Admittedly there are challenges to consider — such as the need to offer access under the trailer, weights, costs, and aerodynamic drag, not to mention the need to ensure they will hold up to Canadian operating conditions. Answers to questions like that will involve material science research, static tests, computer simulations, and dynamic crash tests.

“This is just preliminary research that we’re starting to undertake, but it is showing some promising results already,” Poole said. “We want to have a very good understanding for what works and what doesn’t work.”

Dangerous goods tanks

Those who transport dangerous goods will soon see changes emerge in Canada Gazette Part 1 to more clearly identify those who are considered “competent” to perform such work.

Rather than generally requiring adequate training, the updated rules will require general awareness as well as competence in job-specific work, said John Handrigan, team lead with Transport Canada’s transportation of dangerous goods program.

“Guidance material, it’s already been developed,” he added.

Other regulatory changes that emerged this spring apply to the safety standards for highway tanks and TC portable tanks.

New tank securement requirements for CSA B620:20 tanks offer “more-realistic loading requirements,” Handrigan said. So, too, have regulators updated the damage protection demands for the TC 331 tanks used to haul propane, and TC 338 and 341 cryogenic tanks, he said.

The TC51 portable tanks, which had been removed from standards in 2014, have been reintroduced — but now they include several provisions to allow for things like bottom openings if the tank is protected.

Propane tanks, meanwhile, now have to be inspected every 10 years, and that process includes changes such as new calibration requirements that apply to the pressure gauges used for the tests, revised thickness testing requirements that apply if an area of a tank is corroded, and higher safety standards for pneumatic tests. Safety relief devices now have to be set at 110% of test pressures.

There are even updated training and qualification requirements for tank inspectors, and those represent some of the biggest changes of all, he said.

Meanwhile, updated B621:20 rules allow non-rectangular TC44 tanks to be used to transport things like gasoline and jet fuel as well as diesel. Markings for manually activated emergency shut-offs, while a common practice, are now mandated as well.

As for those who are loading or unloading the equipment? They now need to use at least two chock blocks to ensure the trailers don’t roll away.

New shutoff marking requirements have also emerged in the B622:20 rules that apply to tanks hauling propane and anhydrous ammonia, along with the requirement to use two wheel chocks when loading and unloading.

In the midst of it all, Handrigan stressed the need to ensure that anyone remounting a tank on a vehicle is qualified to do the work.

“There have been instances where facilities, they’ve been doing work they’re not registered to do,” he warned. “In some instances, the facilities didn’t have acceptable procedures.

“Do some due diligence.”

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.