Trailer makers struggling to meet demand

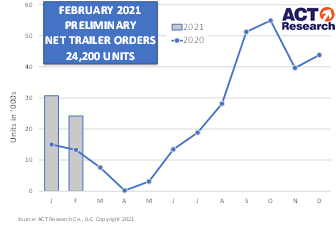

Demand for new trailers remained strong in February, with 24,200 orders placed, but the backlog continues to grow as manufacturers wrestle with supply and labor shortages.

February’s preliminary net orders reported by ACT Research were up 82% year-over-year, but down 21% from January bookings.

“Given last year’s Covid-related softer economy, year-over-year improvement for net orders is a foregone conclusion over the next few months. February’s sequential decline in net orders was a bit larger than seasonal patterns would project, but was directionally correct,” said Frank Maly, director CV transportation analysis and research at ACT Research.

“Preliminary results for the month still show that the industry backlog continued to grow in February, reaching the highest point since March 2019. With many OEMs reporting their capacity committed for the year, there may be some reluctance to push the backlog horizon out even further, on both the part of OEMs and fleets.”

Maly added, “The backlog horizon will be pulled forward in response to higher OEM build rates. February prelims indicate that goal remains elusive, with minimal increases in production rates last month. Our discussions indicate that staffing remains the primary headwind impeding higher production, with component and material supplies also noted as concerns. Fleets want to add more trailers to their operations, but would certainly like more advantageous delivery timeframes.”

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.

Labour and material shortages will slow down production. Labour costs in Ontario are up over 10 percent in the last 18 months for many manufacturing and construction jobs. We need to have a long term plan get away from this just in time model and gov and private stockpiles of key items and materials from lumber to computer chips to oil to rubber.