Biodiesel targets fuel debate in trucking industry

The race to slash greenhouse gas emissions is on, and it’s extending beyond the promise of future battery-electric trucks or hydrogen fuel cells. Look no further than the fuel in truck saddle tanks for an example.

Federal regulators are in the midst of collecting comments for a new Clean Fuel Standard that will force fuel suppliers to lower the carbon intensity of liquid fuels across the board. And Manitoba recently released plans to mandate some of the highest biodiesel blends in the country.

Every drop of diesel already includes some biodiesel during the course of a year. Canada requires an annual average of B2 – a mixture that includes 2% biofuel. Manitoba upped its limit to B3.5 this year, and announced a B5 limit effective Jan. 1, 2022.

To some members of the province’s trucking industry, the higher percentages have the makings of a bio hazard.

“It’s the theory that people fall in love with,” says Bison Transport president and CEO Rob Penner. “I know for sure I’m going to have maintenance issues.”

Waxing fuel, clogging filters

One of the key challenges comes with the way biodiesel tends to “wax” in cold temperatures. Such crystals will form in any diesel fuel, clogging fuel filters and bringing engines to a standstill. But biodiesel will wax at a higher point on the thermometer.

This isn’t much of a problem with a B2 mandate. Fuel suppliers can hit that target by dispensing B5 in warm weather and a full petroleum-based diesel in the winter. But a B5 target means there will likely be some biofuel in the mix during cold months, and even double-digit percentages in warmer weather.

The maintenance issues that emerge will include things like shorter oil drain intervals, Penner says.

“Going back to a 50,000-mile (80,000-km) oil change literally doubles our oil consumption. Nobody talks about that.”

The criticism is particularly striking because the fleet is widely recognized for other green initiatives.

Bison has fired owner-operators who use “delete kits” to strip problematic emissions controls from trucks. It has been an early adopter of fuel-saving strategies from aerodynamic enhancements to lightweight components and late-model engines. It’s testing fuel cells in Alberta, and placed orders for early electric trucks. Those all reduce greenhouse gases.

“We are all about sustainability and we’re highly supportive of real strategies that actually get us there,” Penner stresses.

“This is not about the truck. This is about the oil and gas industry. Why would you pin me with a cost I can’t recover?” he asks. “We’re not the problem you’re trying to attack, but we end up bearing the brunt of it.”

Increasing biodiesel blends

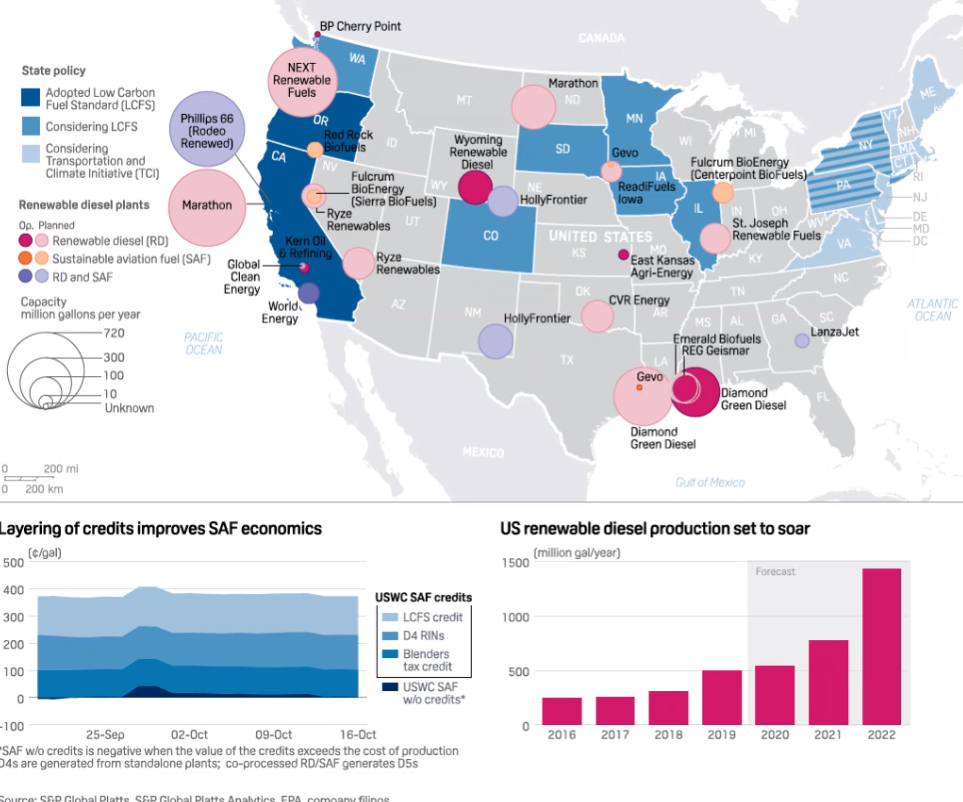

Biofuel percentages have been gradually rising across North America for years, even if they don’t grab headlines like the promise of electric vehicles.

Canada’s requirement for a B2 biodiesel blend can be traced to Renewable Fuels Regulations established in August 2010. They’re the same rules that require 5% ethanol blends in gasoline. Ontario and B.C. have since increased their annual biodiesel limits to 4%. Quebec is proposing its own B4 requirement by 2025.

Truckers are not escaping higher blends by filling up in the U.S., either. Under U.S. Environmental Protection Agency (EPA) rules, anything up to a B5 is even treated like an additive. No special labels are required at the fuel island, so there’s no way to know if these levels are present. Illinois offers tax incentives on fuel above B11. And Minnesota requires a B5 in winter and B20 during the rest of the year.

“With respect to biodiesel, Canada is quite frankly the land that time forgot,” says Ian Thomson, president of Advanced Biofuels Canada. Several truck stop chains such as Pilot Flying J, Travel Centers of America, and Loves Travel Stops even offer B20 versions of the fuel.

“The Americans have completely obliterated the compatibility questions,” he says. “You simply can’t deny those fuels work.”

How well do biofuels work?

The question is whether the higher biodiesel blends will work as well as the fuels that came before them.

The Manitoba Trucking Association (MTA) and fleets like Bison are expressing concerns about the potential effect on warranty coverage. Even Natural Resources Canada admits there is a potential threat here.

“Some manufacturers may limit the scope of their warranties by stating that failures from the use of any fuel cannot be attributed to a factory defect,” the regulator says on its website. “Therefore, the cost of repair under these circumstances (if any) would not be covered by certain warranties.”

The Engine Manufacturers Association notes that anything up to a B5 shouldn’t cause problems with engines or fuel systems. And NREL – the U.S. National Renewable Energy Laboratory – concluded blends of up to B20 wouldn’t be a problem unless the fuel oxidizes.

“Most diesel engines are approved to operate on blends of high-quality biodiesel up to 20%, and a few new engines on blends up to 30%,” says Kristen Gifford, spokeswoman with the Diesel Technology Forum. “Some older engines still in use may be approved to operate on blends at 5%.”

“Normally lower concentrations like B5 are not an issue, but as the concentration increases there can be concerns,” says Patrick Holmes, Volvo Group senior engineer.

Another challenge is that the quality of biodiesel can vary. “Despite fuel standards for biodiesel – such as ASTM D6751 and ASTM D7467 – there are still concerns in blending and overall quality of the fuel,” he says.

Contaminants like phosphorous, sodium, calcium, magnesium and other metals can also plug aftertreatment devices – some of the very equipment mandated to control emissions in the first place.

Older engines, other challenges

The potential maintenance challenges are more pronounced for older equipment without any warranty coverage.

“Biodiesel doesn’t play very well with copper,” explains Len Copeland, Daimler Trucks North America’s product marketing manager – Detroit branded products. There’s none of that material in a late-model engine like a DD15, which also includes seals compatible with blends up to a B20. But there’s still plenty of older models on the road.

“In prior years, the biggest discussion around biodiesel was about seals and rubberized material,” says Volvo’s Holmes. “There are material solutions that exist [in newer engines], but it still impacts the above-B20 blends, based on how the energy from fuel is converted to mechanical work. This may impact digital sensors, algorithms, diagnostics, aftertreatment systems.”

But engines of every age may require some added attention at a B5 blend or higher.

“You need to keep your eye on the fuel filters. You need to keep an eye on your oil drains,” Copeland says.

Biodiesel blends of B6-B20 might require fuel filters to be changed at half their normal intervals.

Some fleets have turned to additives that promise to prevent gelling, lower cold filter plugging points, and clean deposits in fuel injectors.

“This gets to be very kind of personal,” says Allen Schaeffer, executive director of the Diesel Technology Forum. “If you look at the manufacturer recommendations and any government requirements, as long as the fuel is meeting [BQ9000] spec’s, then theoretically it should be fine.”

“Today’s biodiesel is a much higher quality refined product than people might have seen in smaller batches 15 to 20 years ago,” he adds.

“There’s a lot of commercial additives out there,” Copeland says of the offerings. “There’s none we recommend.”

‘Nothing for Manitoba’

Penner remains unconvinced that Manitoba should be leading the charge toward some of Canada’s highest biodiesel blends.

Setting aside unique maintenance challenges like fuel filters, shorter oil drain intervals, a potential drop in performance, a slight drop in observed fuel economy, and new strategies to maintain storage tanks, he wonders why his province has decided to choose biodiesel as one of its biggest tools to meet GHG emission targets.

“This does nothing for Manitoba,” he says, noting there are no high-volume producers in the province.

Biofuels became a big topic of discussion when China began turning away Canadian canola, but those crops have since found other markets, he says. “There’s zero biofuel being produced in Manitoba. It’s coming [by ship] from Singapore.”

“There’s huge transportation costs and that’s the reality of shipping this much fuel product around the globe,” says Terry Shaw, executive director of the Manitoba Trucking Association. “I’m not aware of any local agricultural content that goes into biodiesel.”

Most of the fuel made in Canada is exported to U.S. markets that offer tax credits to blenders. While there are 28 biofuel production facilities on this side of the border today, about 2/3 of that capacity is based in Ontario and Quebec, with the majority devoted to ethanol for gasoline.

A higher fuel price

No matter where the biodiesel is sourced, though, it comes with a higher price at the pumps.

Biodiesel or HDRD blends increase the annual fuel costs of a typical longhaul trucker by about $235 per year, according to the Biofuels in Canada 2019 report by Navius Research. “Costs are higher for diesel consumers since roughly half of the renewable fuels blended into the diesel pool is the more costly HDRD.”

That Hydrogenation-Derived Renewable Diesel is cracked like traditional petroleum-based fuels.

Shaw is confident the trucking industry would make a bigger dent in GHG emissions if it was supported by the estimated $40-50 million per year that a three-point increase in biodiesel blends will cost. More rebates for battery-electric equipment could encourage fleets to experiment where the equipment makes the most sense.

Then there are options like hydrogen fuel cells. Aerodynamic upgrades. Regulatory changes to support wide-base tires.

“Why is government not supporting that work as opposed to creating policy that conflicts with it?” Shaw asks. “Biodiesel is a temporary measure at best.”

Schaeffer points to one factor that could be attracting regulators. A higher biofuel blend can be applied to the entire trucking industry that will be dominated by diesel engines for years to come. Even if the related GHG reductions are relatively small per engine, that adds up to big totals toward broader targets. No hydrogen fuel network needed. No charging stations necessary.

As for even higher biodiesel limits, there might be more limitations to that – especially when it comes to engines built to meet the next round of emissions standards.

“The engines are already so close to zero emissions, this next step down will be more challenging,” Schaeffer says. “That’s where things like fuel quality and what goes into the engine starts mattering more and more.” Biofuel can have a cooling effect, which could generate higher levels of NOx, which is treated through SCR.

“The diesel engine is going to be around for a while,” he says.

Shaw believes the opposite can be said about biodiesel.

“Not only is it not the fuel of the future,” he says, “it’s not the fuel of today.”

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.

As a fleet owner in the U.S., I have first hand experience and knowledge of how class 8 over the road tractors respond to biodiesel blended fuel. Biodiesel causes a more extreme drop in fuel efficiency than just “slight” as the article mentions. I have tested my own fleet on zero biodiesel (or at least less than B5) up to B20 and seen differences ranging from 0.25mpg up to 1.5mpg. Those are not “slight” decreases. They are significant and could be the difference between making a profit or not in an industry with razor thin margins. Trucks must burn through more fuel just to use biodiesel. Additionally, there are extreme maintenance issues associated with the use of biodiesel. Not only are oil and fuel filter intervals drastically reduced, but every single heavy duty diesel engine manufacturer clearly details in their warranty documentation that engine repairs resulting from the use of more than 5% biodiesel blended fuel are not covered items under the warranty. Yet, we in the U.S. are forced to run up to 20% biodiesel in states where the government provides considerable tax incentives to fuel vendors. These maintenance issues, decreased fuel efficiency, and the production and blending of biodiesel itself all have significant ancillary increases in GHG emissions that are not even considered when biodiesel agendas are pushed. If they are considered, they are shoved off and dismissed as they would most definitely haul up a lot of pushback on the use of biodiesel when properly addressed. All of the biodiesel regulations and incentives are done under the myopic costume of GHG emissions reductions, and do not take into account the real downstream consequences associated with the forced and incentivized use of biodiesel as long as political climate change rhetoric can maintain its cozen appearance. So, “as for me and my fleet, we will fuel on the yard.” I have attempted to take matters into my own hands as much as I can and have implemented the use of on-site bulk fuel at my terminal in AR where I can control the quality and biodiesel blend amounts. I encourage and push the use of our on-site fuel in our trucks as much as is possible for an over the road long haul trucking company. Feel free to reach out to me in you would care to discuss this topic with me further.