Using AI to improve efficiency, safety

LONG BEACH, Calif. – Fleets can tap into artificial intelligence (AI) to repair vehicles more efficiently and to train drivers in real time, according to speakers at ACT Virtual Aug. 27, during a connectivity panel on the power of AI.

Conal Deedy, director of connected vehicle services with Volvo Trucks North America, noted Volvo is now monitoring 250,000 trucks in North America. While doing so, it is able to apply machine learning to understand what is happening with the vehicle 24/7, while also compiling a detailed history of that vehicle and others like it.

“It’s really important that we have actions that come out of this information that can be acted on to improve the customers – not just produce more data,” Deedy said.

Algorithms are created to identify previously unidentified relationships between certain trends and behaviors. For example, a certain fault code when coinciding with a software trend on a certain model year may be the precursor to a failure fleets can address before it happens.

The biggest example of how AI is used for service is remote diagnostics. Volvo monitors 50 million sensor readings a day, all processed in less than half a second, and creates 4,000 cases per day through its remote diagnostics platform.

“We contact customers, letting them know the severity of the yellow light they are seeing and what we recommend should be done with that vehicle,” Deedy explained. When a fault is displayed, Volvo’s able to tell the customer what needs to be done, which parts are required, where to take it for service, and can even provide step-by-step repair instructions with diagrams.

“It helps the repair facility know what type of technician is needed, what tools are needed as well as parts,” he said. “It really helps facilitate that repair process and get that truck out faster.”

Trucks pre-diagnosed using remote diagnostics spend 38% less time in the shop compared to a traditional visit. AI has also reduced non-critical alerts by 70%, allowing most trucks to stay on the road to complete their delivery despite a fault code being present.

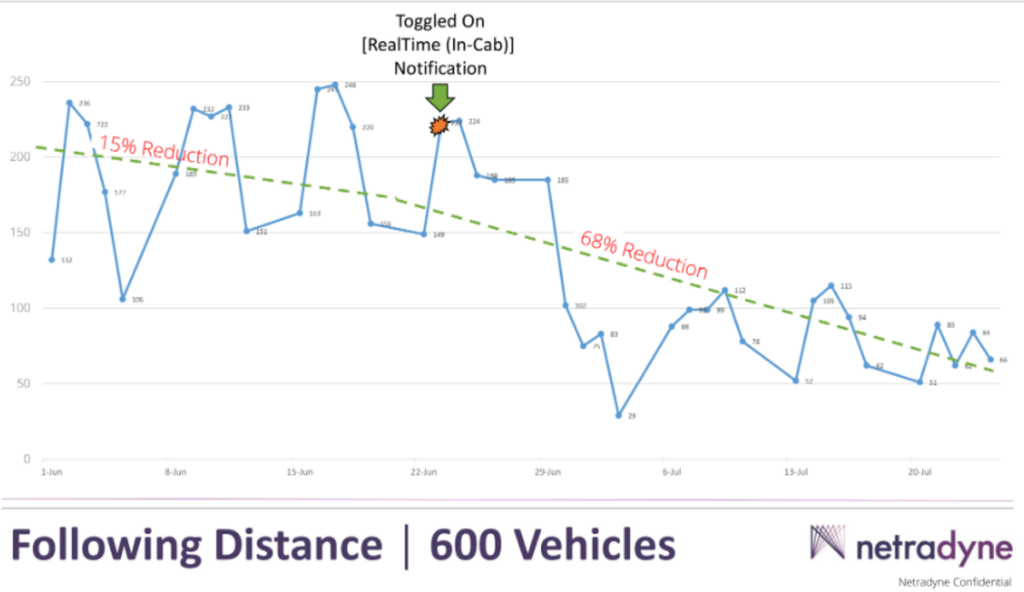

AI can also be used to coach drivers in real time, according to Adam Kahn, president, fleet busines with Netradyne. He points out the average longhaul truck travels more than 100,000 miles a year, or 500 minutes a day, so a fleet of 250 trucks spends 125,000 minutes a day driving down the road. How does a fleet effectively monitor those trucks? With artificial intelligence, he said.

“One person can’t sift through 125,000 minutes of data points,” he pointed out.

Netradyne’s in-cab camera processes data in real-time and makes observations to the driver immediately through alerts and notifications. For example, when a driver rolls through a stop sign or follows another vehicle too closely, the driver will immediately be warned – no waiting for the safety manager to analyze the video and summon the driver for coaching. Kahn said Netradyne’s AI platform can identify when a driver has picked up a cellphone and remind the driver to put it down within 11 seconds.

“In 11 seconds, our system has recognized a dangerous maneuver and invoked changes,” he explained.

Stefan Heck, CEO and founder of Nauto, noted 71% of collisions are caused by distracted driving, and 80% of those involve digital devices. The Nauto platform fuses AI and historical data to prevent collisions before they happen by monitoring the vehicle’s surrounding environment and determining the riskiness of maneuvers in those specific conditions. For instance, Heck explained the risk of an incident goes up eight-fold when it’s raining at a rate of 5 mm per hour, drivers are 50% more likely to be in a crash while smoking, and that rush hour is four times more dangerous than other times of day.

Every few milliseconds the system is determining how likely there is to be a collision and warning drivers when a collision risk is present.

Heck said the system can reduce collisions by a third through warnings, and another third through improved driver behaviors. “Within two weeks we can get an 80% reduction risk,” he said.

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.