Volvo showcases futuristic SuperTruck 2 at MC&E

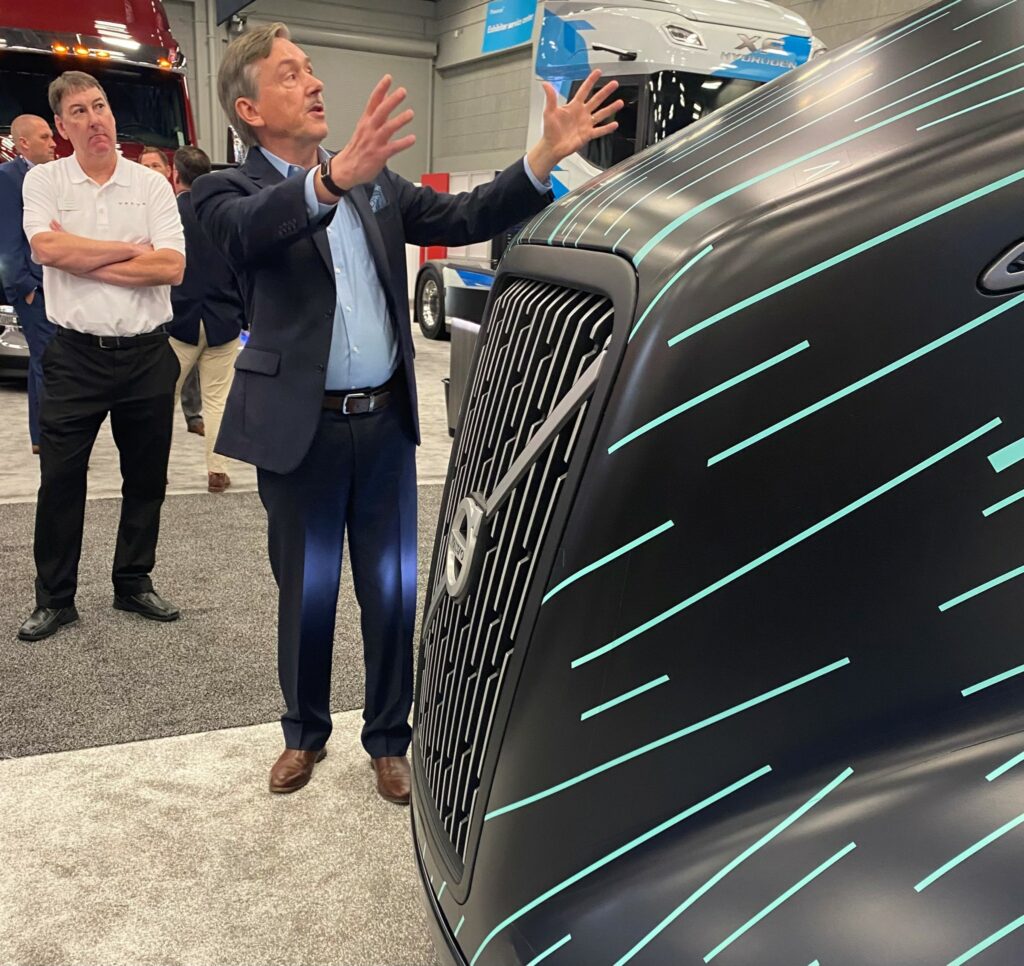

Volvo Trucks drew a crowd to the American Trucking Associations Management Conference & Exhibition with its futuristic SuperTruck 2, the fruits of a partnership with the U.S. Department of Energy aimed at doubling freight efficiency.

Volvo surpassed that target compared to a 2009 baseline, and even bettered its own internal target of 120%, coming in with a final product that improved freight efficiency by 134%.

“We did not test this on flat roads and constant speeds,” said Eric Bond, principal engineer on SuperTruck 2, while giving trucking journalists a walkaround of the truck. “The route was driven at posted speed limits with variable terrain and traffic — normal conditions customers would drive this vehicle in.”

Considering trucks and trailers

Keith Brandis, vice-president of partnerships and system solutions, said the SuperTruck concept began in the late 1990s with a focus on individual components that could improve truck efficiency. The goal was to design a 10-mpg (23.52 liters/100 km) truck, something that at the time seemed to be a big ask. Participating OEMs such as Volvo took a component approach to improving efficiency but felt the rewards would be bigger if they took a more holistic approach to an entire truck and trailer combination.

“Why not put it all together in a complete truck?” Brandis asked. That’s what happened when the DoE agreed to funding the SuperTruck 1 program, through which Volvo was able to boost freight efficiency by 88%, above the DoE’s target of 50%.

To gain even further efficiency improvements, Volvo knew it would take a team approach. It worked with 10 partners – including two fleet customers – on the second version of the truck.

“We found having a team approach was the only way we could stretch the envelope,” Brandis said.

Tires, aerodynamics, and more

Michelin provided 19.5-inch tires with a new tread compound that’s not been commercialized. Wabash designed the lightest-possible trailer and boat tail, made of composite materials. Bergstrom developed a heat pump for inside that cab that would keep drivers comfortable while running the HVAC electrically.

“Every one of them had weight targets, or aerodynamic or cost performance targets they had to hit,” Brandis said.

Aerodynamics and weight savings were both needed to meet Volvo’s targets. It went with a 4×2 configuration to reduce rolling resistance and weight, but also had to maintain a gross combination weight of 65,000 lb. Ride height was lowered two inches for improved aerodynamics. A smaller cooling package was designed to improve airflow, and every conceivable gap was closed. Even the bolts were counted, and the minimum used.

The driveline was made of 3D-printed composite parts. Traditional mirrors were replaced with tiny cameras, with displays mounted inside the cab.

“The biggest challenge was this windshield,” Brandis said. “The curvature. Moving the A-pillars back and the sloping meant we needed a complex piece of glass that had to give optimal qualities drivers need to see the road ahead, but also, how do you get windshield wipers to work on this complex piece of glass?”

Powertrain and weights

Powertrain experts had their own ideas, including a 325-hp, 11-liter engine with smaller exhaust aftertreatment system, but they had to work alongside aerodynamicists to ensure the entire truck would achieve its overall efficiency targets.

Tare weight was reduced to 27,000 lb. to accommodate 38,500 lb. of payload, thanks in part to aluminum frame rails and crossmembers and a special suspension. “We were taking out every pound we could find,” Brandis said.

Even the interior was redesigned. The driver enters from a flush-mounted door positioned further back along the cab, over retractable stairs that tuck away when not in use.

“We challenged our own thinking about what is the cab concept of the future and how might it change,” Brandis said, noting it was designed assuming drivers will spend more time at home in the future and less time living out of the truck. “But it still had to have an office environment, a relaxing entertainment area, and the Hours-of-Service requirements for sleeping and resting.”

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.

AS A FORMER HEAVY STRAIGHT TRUCK CROSS BORDER DRIVER BETWEEN TORONTO AND EASTERN U.S. SEABOARD, THERE IS NO NEED ANYWHERE FOR ANY OVER THE ROAD TRUCK TO SITE SO HIGH. PUT AIRBAGS, ON BOTHE THE TRAILER AND TRACTOR TO LOWER THEN 6 OR 10 INCHES. USE THE AIRBAGS TO RAISE THEM AT LOADING DOCKS ONLY. NYC LOADING DOCKS ARE THE WORST, EVERY ONE OT THEM ARE A DIFFERENT HEIGHT.

THE FUEL SAVINGS BY LOWERING THE FRONTAL AREA BY 10 NICHES WILL PAY FOR THE EXTRA COST OF A HIGHWAY TRUCK AND TRAILER. SUPER LOW AIRBAG SYSTEM. JUST 2 OR 3 INCHES IS A JOKE. GET SERIOUS AND GO FOR A 30 PERCENT FUEL SAVINGS.

AND TO SAVE ANOTHER 25 TO 30 PERCENT ( REAL WORLD ) ON FUEL USE, USE A PROPANE BOOST SYSTEM. PROPANE HAS A 36 TO 37 PERCENT HYDROGEN CONTENT, SO THERE WILL BE MUCH LESS OR NONE, CARBON BUILDUP AND ALMOST NO REGEN REQUIRED, IF EVER. BEFORE MY TRUCK DRIVING DAYS, I HELPED MANAGE A FLEET OF 380 PROPANE FUELED TAXI CABS. IN 30 YEARS WE PUT 25 MILLION MILES ON THEM. THAT’S 40 MILLION KM. THE PROPANE MOLECULES ARE 4 TIMES SMALLER THAN THE DIESEL FUEL DROPLETS AFTER THEY ARE INJECTED INTO THE ENGINE. ONE 7 LITER CUMMINS GOT A 32 PERCNET INCREASE IN FUEL MILEAGE AND A BIG BOOST IN TORQUE AS WELL. SHIFT SOONER, WITH HIGHER TORQUE AND SAVE EVEN MORE FUEL AND REDUCE NOISE. OUR GASOLINE V6 AND V8 CHEVS RAN 750 TO 850 K IN A 5 YEARS PERIOD. ONLY MINOR ENGINE WEAR AND NO ABNORMAL OIL CONSUMPTION BECAUSE THERE WAS ALMOST NO INTERNAL ENGINE WEAR. THE CATS DID NOT PLUG UP IN THE 5 YEARS WE KEPT THEM ON THE ROAD. BY THE WAY, IN THE TORONTO AREA, PROPANE IS SELLING OVER THE PAST 6 MONTHS FOR 95 CENTS A LITER AND WITH A FLEET DISCOUNT CARD, SAVE ANOTHER 8 CENTS ON TOP OF THAT.