Revisiting the spring vs air ride trailer suspension debate

The debate over spring vs air ride trailer suspensions is far from over, even if air ride has emerged as the decisive winner in the marketplace.

Some fleets are taking a fresh look at the virtues of spring suspensions and view them as an opportunity to reduce maintenance and lower costs. Scott Bartlein, fleet manager for Barry Trucking, gave a balanced view of both suspension types when speaking at the Fall Meeting of the Technology & Maintenance Council. He noted cargo packaging and load securement equipment has evolved over the years, providing better cargo protection.

Spring ride suspensions are lighter-weight, affording the opportunity to increase payload. Bartlein said they’re two to four times less expensive to maintain than air ride, and if you’re pulling double trailers, they’ll place less demand on your tractor’s air system. Spring ride suspensions are also easier to inspect, which can lead to more effective pre- and post-trip inspections, and potentially fewer roadside violations.

“One size doesn’t fit all and we need to take a fresh look at technologies.”

Scott Bartlein, Barry Trucking

On the other hand, air ride makes sense for cargo that’s fragile or lightweight, especially if it’s coming off a potentially rough sea journey. There are also customers who demand their freight move on air ride suspension-equipped trailers. Some may even pay extra for the privilege.

“I’m not bashing air ride,” Bartlein said. “I think there’s a need for them. All I’m saying is, as fleets we want to keep an open mind. One size doesn’t fit all and we need to take a fresh look at technologies.”

Schneider’s stance

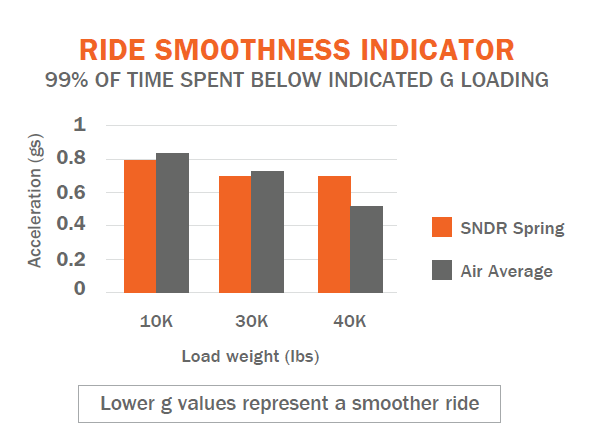

Last year, Schneider published a white paper that revealed the findings of a study it conducted comparing spring to air ride suspensions. The findings were surprising.

“When it comes to trailing equipment, air suspensions are a hot topic, and some believe that air ride is better than conventional leaf spring suspension. In turn, those shippers and carriers are unnecessarily paying more for a system that provides similar or equivalent ride quality,” Schneider wrote in the white paper. It found in comparing the two types of trailers that air ride suspensions did not guarantee a smoother ride. “It’s a myth,” the fleet declared. “Knowing this, Schneider can’t justify spending more on air ride and recommends shippers don’t, either.”

The company’s study found ride quality at the front of the trailer was a function of tractor suspension, with the trailer suspension having little impact. Ride quality at the rear of the trailer, using an industry standard spring suspension, was very close to the four most popular air suspensions tested by Schneider. In fact, under some circumstances, the spring ride suspension provided a better ride quality.

Schneider concluded that with LTL shipments or light loads, the benefits of air ride were “minimal at best.” It also touted spring ride’s benefits, such as being less prone to mechanical issues over its lifecycle, its longevity – generally lasting the life of the trailer – and being immune to certain failures such as punctured, leaking or collapsed air bags.

“Not only are air ride suspensions more expensive to purchase and maintain, which could translate to inflated expense to the shipper, but more importantly, they do not guarantee superior ride quality,” the white paper concluded.

But, not so fast…

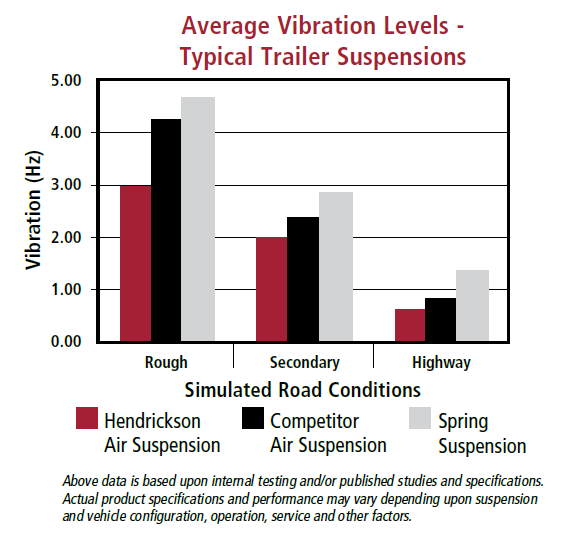

Suspension manufacturer Hendrickson, on the other hand, cites data of its own showing air ride does, in fact, provide a smoother ride among other benefits. The company notes more than 70% of fleets have spec’d air ride suspensions on one or more trailers, for a variety of reasons. It also says air ride suspensions have grown their market penetration from about 12% in 1987 to nearly 70% today.

Hendrickson says benefits include: improved ride quality, better cargo protection, greater flexibility to haul more loads, higher resale value, improved fuel economy and extended tire life.

Measuring vibration over a variety of roads, Hendrickson found spring suspensions performed worse than Hendrickson’s own, and other, air ride suspensions on rough, secondary and highway routes.

“Minimizing the road forces and vibration reflects how well the suspension helps isolate or protect a trailer from potential damage,” Hendrickson wrote in a white paper. “If a suspension has a lower natural frequency, it reduces the forces transmitted to the trailer thus improving the ride quality. Air suspensions in general can achieve very low natural frequencies.”

In its study, Hendrickson found a typical spring suspension has natural frequencies ranging between 2 Hz and 5 Hz, depending on load and other factors, while an air ride suspension can produce natural frequencies below 1.5 Hz.

Canadian fleets prefer air ride

Here in Canada, air ride dominates fleet orders. This could be because of our rougher roads, or the fact Canadians in general tend to call for a more robust trailer spec’ due to the more challenging climate. John DeJong, fleet manager with Trailcon Leasing tells Truck Tech that 75-80% of its new trailer orders come equipped with air ride suspensions.

“Customers are demanding air ride,” he said. “It is perceived to be a better suspension. A lot of (shippers) out there will only load on air ride because of the perception it protects the load better.”

Bob Breadner, president of Breadner Trailer Sales, agrees that there’s very little demand for spring ride suspensions in Canada.

“We have seen some interest, but not enough to call it a trend as of yet,” he said of spring suspension-equipped trailers.

Breadner Trailer Sales ran a pilot within its own fleet several years ago, putting spring ride suspension trailers into service for the delivery of new assets to customers.

“Our drivers didn’t like it,” Breadner said. “When empty they found they didn’t operate as well (as air ride).”

Maintenance requirements

But with air ride suspensions, comes increased maintenance requirements – and sometimes, headaches.

“Air ride does have more components to maintain,” Breadner said, rhyming off: air valves; air lines; air bags; leveling vales; and shocks. All these should be regularly inspected to prevent roadside failures.

“I do believe spring ride will lead to reduced roadside infractions because of how simple they are compared to air ride,” Breadner said. “There are less items to maintain and less items to put the equipment out of service.”

DeJong agreed, noting “Spring is a lot easier – you just check the springs and bolts, see if they’re loose. Maintenance on spring is considerably less, not to mention the cost of purchasing right from the start.”

Air ride suspensions can be problematic later in life, with air bags suffering cracking and dry rot, and leveling valve problems arising. Sliding bogeys can overextend air bags and damage shocks. DeJong said there are so many different types of air bags on the market, it’s important to spec’ the best ones available.

What you choose to do with your trailers at the end of their service life is also a consideration. Air ride-equipped trailers with life left on them are easier to sell, while spring suspension trailers are better suited for storage.

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.

one of my concerns is “empty” miles. our fuel tankers, that are “spring ride” bounce like crazy, causing metal fatigue, premature tire problems, electrical and lighting issues. we are weighing the price of conversion over down time and repairs as we speak

Interesting that roll over threshold isn’t discussed here? I’ve always understood spring ride suspension to be less forgiving in a corner than ai ride? Searching the internet I haven’t found any data to support or refute that. Have any tests been done?