Our Next Energy looks to address three biggest issues facing EV batteries

Battery-electric vehicles, particularly commercial trucks, have a range problem that will limit the applications in which they’re practical for zero-emissions transport. But Our Next Energy (ONE) believes it has a solution to that problem, and others.

The company, with operations in California and Michigan, has set out to double electric vehicle range through advanced energy density, while also improving safety and eliminating thermal events by avoiding cobalt – a common cause of battery fires. If that’s not ambitious enough, it also wants to make the battery supply chain more sustainable.

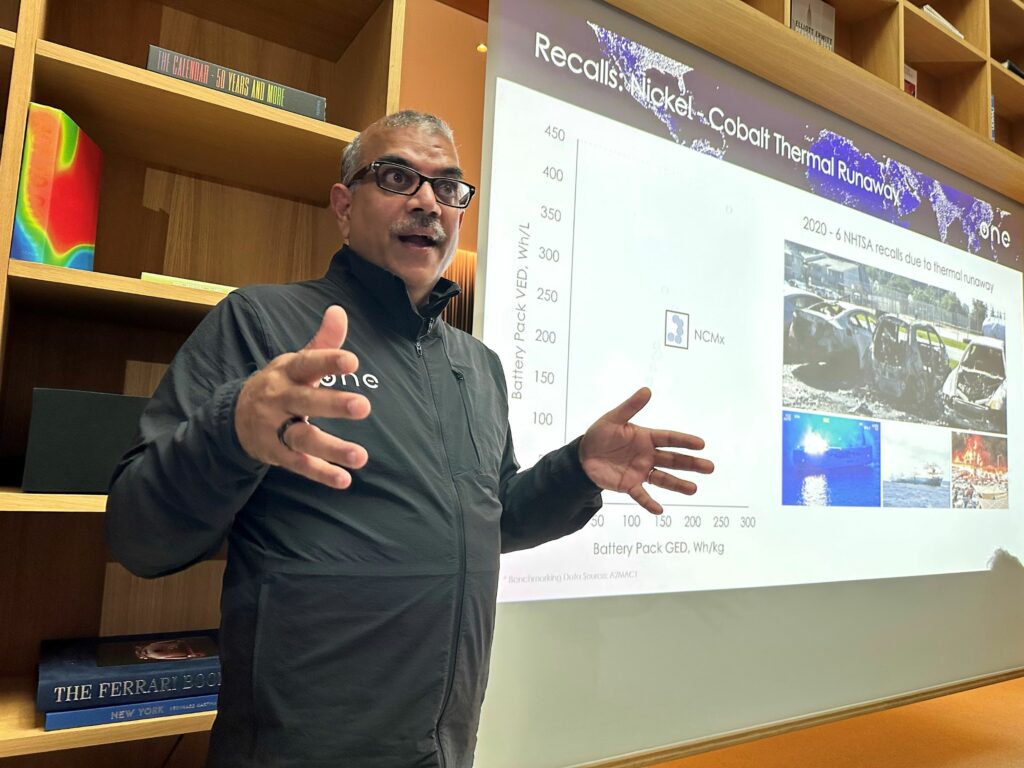

Mujeeb Ijaz, founder and CEO of the company, which has built a battery factory in Michigan, gave automotive and trucking journalists an update on the company’s progress during a House of Journalists event in Munich, Germany.

He was clear about the limitations of current EV battery technologies today. Their real-world range is more likely to be 20-30% less than advertised in real-world conditions, and can drop 40% in extreme weather.

“If you bought a vehicle that loses 40% of its capability in a trip, then range was off by a factor of two times,” he pointed out, adding that won’t be acceptable to consumers or fleet customers.

Eliminating thermal events

And he said thermal events continue to be too common. While they may not often make the news today, this will change if the car market were to be 20% electric, he said. “There wouldn’t be a night you didn’t hear about an EV fire,” he warned, noting cobalt is the leading cause of battery runaway thermal events.

Such incidences could deter consumers and trucking companies from adopting electric vehicles, setting the industry back substantially.

Supply chain diversity is the third hurdle the EV industry must overcome, he added. Battery metals such as lithium, nickel and cobalt are often mined under dubious conditions and subject to price volatility.

“In the history of great innovations in battery technologies there has yet to be a U.S.-born battery company that manufactures its products at scale today,” said Ijaz, who is looking to change that. “Solving one [of these issues] would be really valuable. Solving all three of them would be invaluable.”

ONE was founded in July 2020 with the aim of addressing all three challenges: doubling range, eliminating thermal events, and offering supply chain diversity with U.S.-made batteries less reliant on nickel and cobalt.

“We decided to imagine a solution that can go to work today, that’s the same size, same weight, and has twice the energy [of today’s batteries]. We think that’ll bring the cost down,” he said. “More density – that’s the best way to get to cost — using less materials to get the same result.”

Gemini range extender

ONE’s Aries-branded lithium-ion phosphate (LFP) chemistry battery packs are well suited for commercial vehicle applications, delivering 150 miles (240-km) between charges, without nickel and cobalt. Instead the Aries battery relies on inexpensive and abundant iron as its main ingredient.

The under-development onboard supercapacitor, dubbed Gemini, replenishes the power supply to the primary battery bank, which will offer greater range yet.

“The range extender’s job is to replenish the first battery,” Ijaz explained.

After 150 miles, the vehicle switches to the anode-free manganese-based second cell to charge the LFP cell, providing an additional 450 miles (720 km) of range. The combined 600-mile (1,040-km) range will better today’s commercially available battery packs that rely on nickel and cobalt. And their combined chemistry features 20% less lithium, 60% less graphite, 75% less nickel, and no cobalt, compared to traditional EV battery chemistries.

The dual-battery system will be rolled out in 2026, initially with commercial trucks. ONE has supply deals in place with manufacturers including Motiv, Bollinger Motors, and The Shyft Group. Even without the Gemini range-extender, Motiv published test results showing a range greater than 150 miles (240 km) hauling a three-ton (6,000-lb.) payload on its sixth-generation step vans released this year.

“We do have others in the pipeline,” Ijaz said of the commercial vehicle segment, while acknowledging moving into the Class 8 truck segment will require some more work. The Gemini range extender doesn’t yet have the lifecycle that will be required for Class 8 trucks.

“I think within a few years we will be at the point where we can offer Gemini to Class 8 trucking,” Ijaz said.

The capacity at ONE’s 20-gigawatt battery factory is essentially spoken for, and Ijaz said the company is already “eyeing a second factory.”

When it comes to the third challenge ONE seeks to address – sustainability – Ijaz said recycling of spent batteries will be a key element. Lithium extraction from used batteries will pay for itself. The rest of the battery pack can be recycled back into the steel industry, he said, completing the trifecta when it comes to ONE’s mission.

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.

The Fundamentals for changing to EV’s is wrong headed. CO2 is not the problem, environmentalists say it is. plants need it to stay alive, and absorb the carbon, like wood. Yes, remove the particulates!!

The sun has a diameter 109 times that of the earth, perhaps it has an affect on the weather.

The Prime Minister of the UK has removed EV mandates recognizing the harm that is being done, and the inability to supply Electricity from the grid. This has thrown manufacturing into disarray.

Now the price of gas and diesel are exhilarating, due to North American Government policies, of shutting in oil.

Does any of this make sense?

The WEF and Government Mandates are causing great harm to people’s lives, particularly the poor for no benefit!!!

In any event Steel, Cement, Plastic and Fertilizer take up 75% of fossil fuels, not transportation, where the big push is taking place