Bosch slashes NOx, without adding components

New developments from Bosch could help vehicle manufacturers reduce nitrogen oxide (NOx) emissions so drastically that they already comply with future limits. Bosch engineers achieved these results by refining existing technologies, without adding components that would drive up costs.

Flat Rock, Mich. – Bosch says it has pioneered an emissions reduction technology that can cut NOx emissions to 10% of levels seen with current diesel-powered cars, and without adding components. Not only that, the company says the technology can be scaled up for use in medium- and heavy-duty diesel engines.

The supplier based in Stuttgart, Germany, unveiled the technology in April and offered further details during a North American press event this week.

Alex Freitag, director of engineering with Bosch’s powertrain solutions group, said the new approach to NOx emissions will keep diesel engines in the game for years to come without adding significant costs to the vehicle.

“The value proposition of the diesel engine is maintained with a minimal impact on fuel economy,” he said.

In tests conducted in Germany, a passenger car equipped with a 1.7-liter, 145-hp diesel engine achieved an average NOx output of just 13 mg per kilometer over several test cycles in what Europeans define as an RDE test — that’s real driving emissions. The test cycle includes a combination of urban, rural, and highway driving.

Since 2017, European legislation has required that new RDE-compliant passenger cars emit no more than 168 mg of NOx per kilometer. As of 2020, that limit will be cut to 120 mg. While it’s difficult to translate these numbers for a North American comparison, the emissions achieved with this new technology are already 10 times lower than limits set to kick in four years from now.

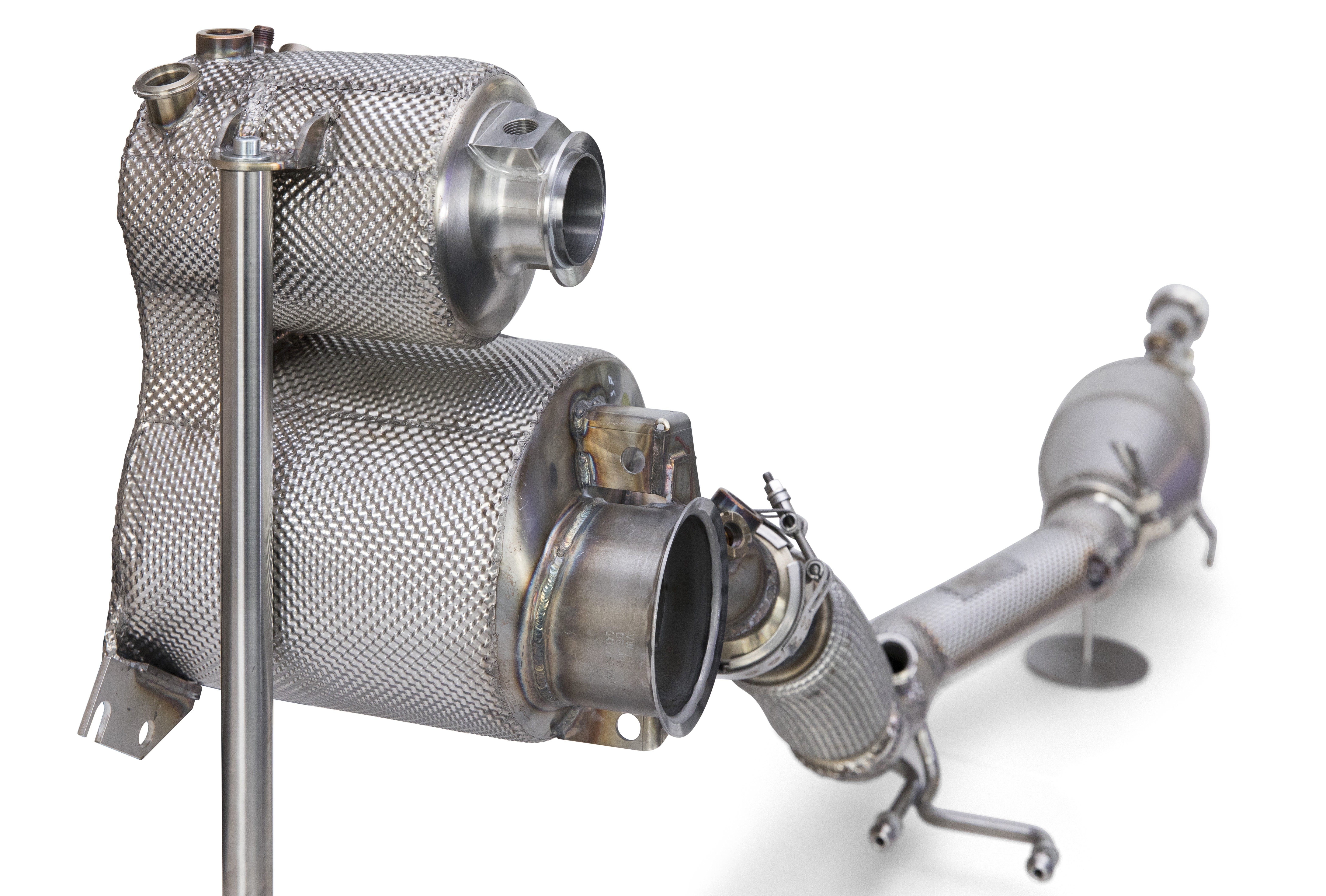

“It’s a combination of technologies that made these reductions possible,” said Freitag. “We keep NOx low in the cylinder through better air management and injection strategies, while using low- and high-pressure EGR, along with a temperature-controlled aftertreatment system using a [diesel oxidation catalyst], [selective catalytic reduction] on the DPF, and a downstream SCR with [diesel exhaust fluid] dosing and low-pressure EGR.”

The system uses high-pressure (2,200 bar or 32,000 psi) common rail fuel injection, with multiple injection events to shape the rate at which heat is released during combustion.

The demands of urban driving cycles forced Bosch to optimize the turbocharger for all driving conditions, and specifically for low-speed high-torque operations (similar to downspeeding). The new software functions reduce the NOx peaks associated with aggressive acceleration and stop-and-go driving.

It all involves a highly responsive airflow management system for the engine. A dynamic driving style demands an equally dynamic recirculation of exhaust gases. Bosch says this can be achieved with an RDE-optimized turbocharger that reacts more quickly than conventional turbochargers. Thanks to a combination of high- and low-pressure exhaust gas recirculation, the airflow management system becomes even more flexible. This means drivers can drive off at speed, and without a spike in emissions.

The aftertreatment system consists of a diesel oxidation catalyst followed by an inline diesel exhaust fluid injector, right before a diesel particulate filter and selective catalytic reduction device. Next in line is a low-pressure exhaust gas recirculation return from the engine, and then a second selective catalytic reduction device with a “clean-up catalyst” to remove any unconsumed ammonia.

Most important, the entire aftertreatment system is carefully temperature controlled to optimize efficiency. The exhaust gases must be hotter than 200 Celsius, although vehicles don’t reach these temperatures in urban driving. Bosch uses a sophisticated thermal management system for the diesel engine that actively regulates the exhaust gas temperature — ensuring that the exhaust system stays hot enough to function within a stable temperature range, and that emissions remain at a low level.

“We can heat or cool the system with a combination of EGR and post-injection hydrocarbon dosing and a proprietary air management technology on the engine side, not the aftertreatment system itself,” said Freitag.

The test on which Bosch returned the astonishing 13 mg of NOx per kilometer used multiple drivers and multiple runs over a prescribed test course in real-world driving, not on a controlled test track. When driving in particularly challenging urban conditions, where test parameters are well above legal requirements, the test vehicle’s average emissions are as low as 40 mg per kilometer.

Bosch’s new diesel system is based on components that are already available in the market. It is available to customers effective immediately and can be incorporated into production projects.

Bosch says it will not make diesel vehicles “any less affordable”, nor will it affect diesel’s fuel efficiency and corresponding carbon dioxide output. “The diesel retains its comparative advantage in terms of fuel economy, CO2 emissions, and therefore climate-friendliness. Diesel will thus remain a climate-friendly option,” the company said in a press release.

And Bosch says the technology is scalable.

“This was tested on a 1.7-liter, four-cylinder passenger car diesel engine, but we see no reason why it can’t be introduced in larger vehicles,” said Freitag.

One of the big hurdles faced by truck and engine makers going into Phase 2 of the greenhouse gas rules will be the demand for simultaneous cuts to NOx and carbon dioxide. Fuel mileage usually suffers with efforts to reduce NOx in-cylinder, but this solution may offer opportunities to achieve both, and without significant penalties.

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.