Volvo Trucks rides high on innovation, investment

DUBLIN, Va. — Volvo Trucks North America is on a roll.

In the year since Peter Voorhoeve took over as president of VTNA, the company has unveiled a slew of technology updates, and announced fresh investments worth hundreds of millions of dollars at its flagship plant in Dublin, Va.

On Wednesday, VTNA is hosting a seminar, Volvo Trucks – Connecting the Bigger Picture, when Voorhoeve is expected to reveal more details about the company’s plans for 2020.

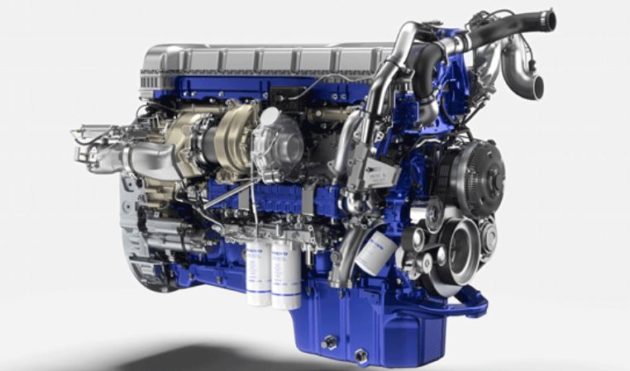

One of the biggest recent announcements was the launch in August of the Enhanced Turbo Compound Engine for VNL models.

New fuel-efficient engine

This next-generation technology will provide up to 3% more fuel efficiency over the current 13-liter Turbo Compound engine, the D13TC, the company said.

Overall, it delivers up to 11% fuel savings compared to model-year 2015 trucks, VTNA said.

“We developed our first generation of the Turbo Compound engine in 2017, and since then almost 300 million miles have been logged, validating up to 8% fuel-savings benefits,” said John Moore, product marketing manager at VTNA.

“This new D13TC builds upon this game-changing engine technology, further increasing fuel efficiency by up to 3% over the current D13TC engine, saving approximately $1,200 per year per truck, based on the average fuel price and 125,000 miles per year.”

Volvo Active Driver Assist

Just months earlier, the company announced the release of a comprehensive collision mitigation system, known as Volvo Active Driver Assist (VADA) 2.0.

It will be made standard in the new Volvo VNR and VNL models, and optional on VNX models later this year, the company said.

The system enhances the original VADA platform by integrating radar and camera capabilities to help drivers maintain a safe following distance through alerts and improved traffic awareness, as well as emergency braking to reduce the risk of collisions.

The technology offers enhancements to many features including Automatic Emergency Braking (AEB), Lane Departure Warning (LDW), Highway Departure Warning and Braking (HDB), Adaptive Cruise Control (ACC) with Cruise Auto Resume and Driver Awareness Support, the company said.

AI to improve safety

In June, Volvo showcased a project designed to strengthen safety capabilities for the trucking industry through automation, using artificial intelligence.

The proof of concept was developed in collaboration with automated vehicle software provider Perceptive Automata and customer Dependable Highway Express.

It leverages artificial intelligence that reads the intention and awareness of vulnerable road users such as pedestrians, cyclists and motorists to enhance the situational awareness of truck drivers, Volvo Trucks said.

New investment in Dublin

Also in June, the company announced a $400-million investment over six years to upgrade the New River Valley, Va., plant that produces all Volvo trucks sold in North America.

The plan includes expansion of the industrial footprint and installation of a variety of state-of-the-art equipment that will improve plant efficiency and deliver even higher product quality for customers, it said.

The investment will create 777 new jobs.

“The outstanding product line currently produced at NRV has strongly positioned Volvo Trucks for the future,” said Voorhoeve, the VTNA president, at the time.

Expansion of 3D printing technology

And just last week, the company said it is expanding the use of 3D printing to make components at NRV.

“After years of internal exploration with 3D printing technology and fine-tuning, there are now more than 500 manufacturing tools and fixtures in use on the NRV shop floor produced using 3D printing,” the company said.

The technology has helped improve quality and precision by printing exact copies from models, it said.

Dynamic Maintenance Service

Volvo Trucks has also teamed up with Internet of Things company Noregon Systems to introduces Dynamic Maintenance, which seeks to improve fleet operations efficiency through proactive and flexible vehicle-specific maintenance planning.

The new service uses existing connected technologies and data analytics, combined with Noregon’s platform, to enable customized service plans to an individual-vehicle level to improve fleet operations efficiency, the company said.

Dynamic Maintenance leverages intelligence from vehicle data analytics using enhanced software features.

It allows a more accurate approach to planned maintenance needs, and replaces traditional set-mileage scheduled service appointments. Currently, dynamic maintenance is specific to powertrain-related maintenance services in Volvo Trucks, the company said.

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.