How to maintain your HD engine coolant system

The saying goes something like this: “When you take care of something good, that something good takes care of you.”

The same can be said for taking care of maintenance on a heavy duty engine.

Whether you are a fleet manager or an independent owner/operator, maintaining the optimum operating efficiency of any heavy duty vehicle is essential for success. Any vehicle experiencing downtime is costing its owner or manager in repair bills, as well as in earning potential and revenue. When it comes to getting the most out of your heavy duty engine, properly maintaining the various operating systems is the first step to ensure efficient and reliable performance.

Some estimates project that up to 40% of total engine repair costs are related to issues that originate within the cooling system. These repairs, which can begin from something as simple as the neglect of basic maintenance, create unnecessary downtime that affects equipment operations and customer deadlines.

Today’s heavy duty engines are more sophisticated than any previous generation of equipment. While this sophistication allows the engine to address environmental issues regarding exhaust and pollutants, and to squeeze the most power out of engines that are running hotter than ever, they are also far more expensive to repair should something go wrong. To avoid unnecessary repairs, maintaining the modern-day cooling system becomes the essential link to maintaining the entire system.

Every component in the cooling system affects the performance of other vehicle components. Therefore, proper maintenance will ensure the best possible operating efficiencies. The essential tasks for any cooling system are:

- Provide efficient heat transfer and the transport of engine heat to control critical metal temperature

- Increase the cooling index to help prevent boilover and overheating failures

- Provide freezing protection to prevent engine freeze-ups or non-starts in the lowest temperatures

- Provide effective inhibition of corrosion for all cooling-system metals through a wide range of temperatures and operating conditions

Properly maintained coolant systems may utilize several different antifreeze/coolant (AF/C) product technologies to adequately stay on track with maintenance and cooling intervals. From Conventional (Inorganic) Additive Technology (IAT) to Organic Acid Technology (OAT) formulas to Hybrid Organic Acid Technology (HOAT), cooling system AF/Cs have evolved as the sophistication of the heavy duty engine has grown.

If the cooling system is unable to satisfy essential requirements, the heavy duty vehicle’s horsepower, fuel economy, emissions and overall durability may be compromised. Selecting the highest quality coolant products and replenishing at the recommended interval will ensure operating efficiency and optimal performance.

The Challenge Intervals

The most immediate concerns for any heavy duty operators has to be maintaining their heavy duty fleet’s cooling system levels with the appropriate type of antifreeze/coolant, while knowing precisely when the appropriate interval has been reached for recharging or changing the coolant.

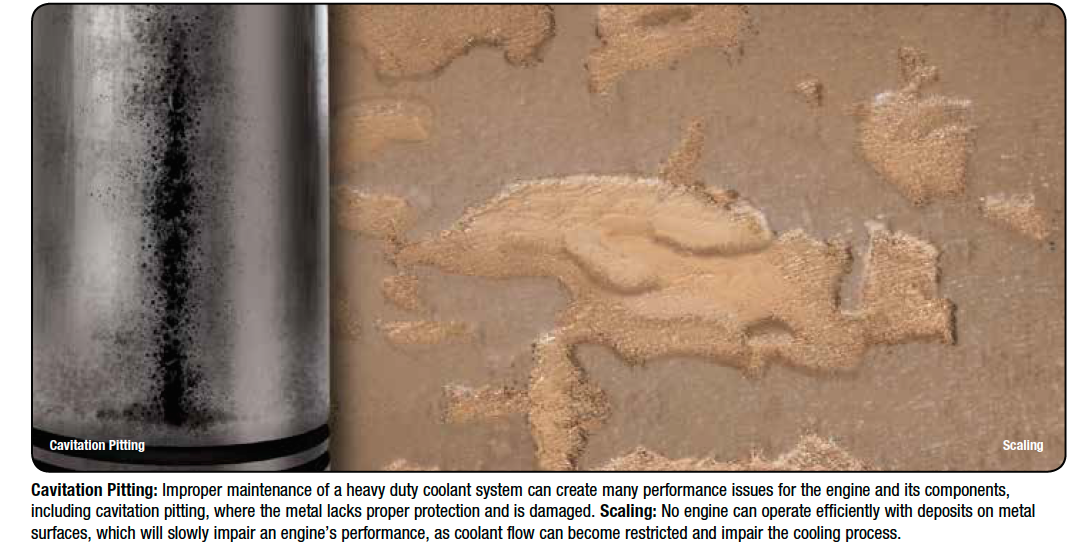

Potential problems that can occur when using the wrong type of coolant range from oil degradation, boilover or freezing to cavitation pitting, rust/corrosion buildup or water-pump failure. Utilizing the wrong type of coolant can also initiate hose leaks, with subsequent high-volume coolant loss, reduced driving comfort and potential engine breakdown.

The American Trucking Associations’ Technology & Maintenance Council (TMC) is an accepted authority for heavy duty trucking maintenance standards. The TMC’s recommended (RP-365 Coolant Maintenance) guidelines are:

- Conventional pre-charged Inorganic Acid Technology (IAO) and Hybrid Organic Acid Technology (HOAT) coolants should be maintained on an engine preventive maintenance interval of 25,000 miles, or as specified by the engine manufacturer.

- Nitrited Organic Acid Technology (NOAT) coolants generally require an extended charge at 300,000 miles, or 6,000 engine hours, to achieve the full 600,000 miles or 12,000-hour service life.

- Organic Acid Technology (OAT) coolants typically provide 600,000 miles or 12,000 engine hours of service life.

Because glycol and water are naturally corrosive, coolant manufacturers add inorganic and/or organic salts and chemicals, known as corrosion inhibitors, to the coolant in order to prevent the cooling-system components from corroding. The very best AF/Cs do more than simply keep the engine from freezing up in cold temperatures or overheating in extreme heat, they also fight metal corrosion within the engine. Rust and corrosion can ruin the efficiency of a cooling system, putting the entire engine at risk. With a myriad of different metals making up any heavy duty engine, it is important to understand the need for inhibitors in the coolant to fight rust and corrosion across all metal surfaces. The correct mixture of coolant with the proper amount and type of inhibitors will guard against corrosion.

As the operation of the engine consumes corrosion-fighting additives, Supplemental Coolant Additives (SCA) must be periodically added to systems with conventional IAC and HOAT coolants to maintain effective corrosion protection. The OAT and NOAT coolants do not require SCAs. The inhibitor package does not determine the level of freeze or boilover protection in the coolant; its only function is corrosion protection.

Cooling-system problems can result from the deterioration of any material within the engine, or supporting systems. Original equipment manufacturers (OEM) provide guidelines for coolants in their engines, but no engine can operate efficiently with deposits on metal surfaces, which will slowly impair an engine’s performance as coolant flow can become restricted, which inhibits the system’s ability to adequately cool or transfer heat from the key components. That’s why it is important to determine the effect a coolant will have on the cooling system/engine parts and materials.

Coolant Colours

The TMC has established recommended colours for varying types of coolants (RP-351). While these are recommendations, the colours are not required and some manufacturers do not follow the colour guidelines. The colour recommendations are:

When choosing the appropriate type of coolant, it is important to understand that you should not assume colours on the packaging are the colour of the contents in the bottle. It is not uncommon to find red or purple labeling, or coloured caps, on products that might not correlate to the content’s colour or formulation. Do not judge a book by its cover and always read the label to be sure you are buying the appropriate coolant for your system.

When choosing the appropriate type of coolant, it is important to understand that you should not assume colours on the packaging are the colour of the contents in the bottle. It is not uncommon to find red or purple labeling, or coloured caps, on products that might not correlate to the content’s colour or formulation. Do not judge a book by its cover and always read the label to be sure you are buying the appropriate coolant for your system.

There are also a number of cooling-system maintenance essentials that should be considered:

- Test coolants regularly for appropriate additive levels

- Only utilize coolant that meets industry standards and performance requirements

- Top off cooling systems using pre-diluted coolant and maintain additive levels at regular service intervals with liquid additives or chemically charged filters.

What type of questions should you ask your coolant supplier before making purchasing decisions?

Modern antifreeze/coolant (AF/C) has undergone decades of research and development as modern engines have become more sophisticated. Add in the demands of different types of engines and operating conditions, and you can understand why it is important to seek change-interval advice from a heavy duty professional.

New coolant systems are best served when they use precisely formulated AF/Cs that have been designed to meet the demands of the current generation of heavy duty engines. Additives in an OAT coolant deplete at a much slower rate than those in fully formulated antifreeze/coolant, but extended-life antifreeze/coolant is not maintenance-free. It should be checked regularly for contamination and freeze point. An “extender” additive package usually is required at the mid-point of the coolant’s life.

Fully formulated extended service interval coolant must be periodically checked for freeze point (glycol content), nitrite (or nitrite/molybdate) levels, and, in some instances, pH. If makeup additives are required, a supplemental coolant additive (SCA) package is used.

A reputable distributor will work with heavy duty fleet operators to responsibly lengthen their AFC change intervals, while not jeopardizing the health and performance of their engines. Given the high-dollar investment in heavy duty equipment, decisions should always be made based on the integrity of the supplier, who develops, manufactures, distributes and stands behind the quality of its products. When in doubt, every manufacturer provides engine specs and coolant recommendations.

Colin Dilley is vice-president of technology for Prestone Products Corporation

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.

Why do Nitrites in NOATs not have to be replenished like they do in an Extended Service Interval coolant? Is it because something else is protecting the iron so the nitrite doesn’t get used?