Prepare for VUCA when managing the supply chain

Although the term VUCA was coined in 1987 by the U.S. Army War College at the height of the Cold War, it hasn’t been in common usage. And thank goodness for that, because it stands for Volatility, Uncertainty, Complexity and Ambiguity – four horsemen that make supply chain management a real challenge.

The term is now gaining in popularity as the rapid and dramatic changes in global trade and commerce are making every day feel like starting from ground zero on supply chain plans.

Jim Tompkins, founder and chairman of Tompkins International, a supply chain technology and consulting group, recently spoke (in an Omnichannel Productions webinar called “VUCA: How do we get back to better”), about how the four variables interact and how organizations might want to act to mitigate the disaster.

First he explained each of the terms:

Volatility is the speed of change and the frequency of change. Change can be instigated by your own company, your competitors or by a natural phenomenon, such as a pandemic or earthquake, Tompkins said.

Uncertainty is lack of predictability, which makes it impossible to define requirements. When you cannot define what you need to succeed, it is then also impossible to optimize operations.

Complexity is the multitude of forces and confounding issues and the blurring of roles.

Tompkins cited the example of retail today: in order to succeed you need to be selling everywhere – online, in store, business-to-business and so on.

Ambiguity is haziness, the inability to get a good read on a situation because it is in flux. Tompkins cited the changing expectations of consumers as a good example.

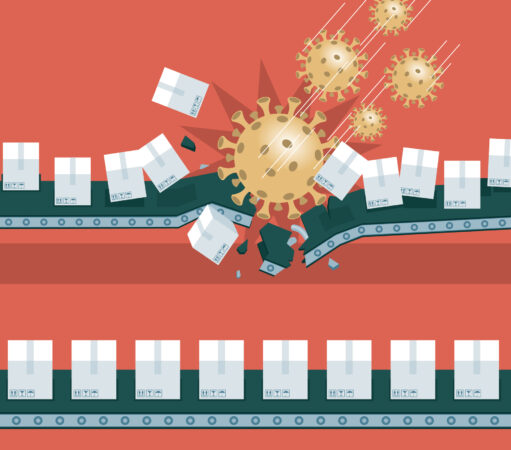

At the moment there are two types of disruption upsetting the world, innovation and crisis. Innovation disruption is the normal cycle of new product and service development, while crisis disruption is the kind of ‘black swan’ event that we are facing with the Covid-19 pandemic. Nobody saw it coming and it has “massive transformational impact”.

“What we have is disruption beyond belief,” Tompkins said. “We’re doing a record innovative disruption and a record crisis disruption at the same time. It’s VUCA on steroids.”

The pandemic is grouping companies into four types, based on how they were doing in December 2019 to now, Tomkins said. They are:

- Boom to boom – These are companies that were doing well in December and now are doing even better. Walmart is one example – business is booming and its stock is up now over the end of 2019.

- Boom to doom – These companies were looking forward to a good 2020, but have had the rug pulled out from under them. Air carriers, and hospitality industry players are in this group.

- Doom to boom – Flat in December, companies in this group have experienced an unexpected surge in business due to the pandemic. Clorox, for example, was flat in Dec and now can’t meet demand for its disinfection products, wipes. Demand is five times what they can produce, Tomkins noted.

- Doom to tomb – Struggling already in December, these companies are now calling it quits. Just a few examples include Aldo Shoes, British fashion retailer Debenhams, Pier 1 and many more.

Tomkins explained what organizations can do under these circumstances. The key is to be able to reinvent and be adaptable. He calls for “optionality not optimality”. Optionality is achieved by creating numerous scenarios and being able to pivot between them as circumstances dictate.

VUCA creates uncertainty, which means predicting the future is impossible. In a normal supply chain network, design initiative managers would look at four to five-year requirements, capital expenditures and so on, and optimize the operation to meet expected requirements. In other words, designing to demand plans.

However, if you don’t know the requirements, you cannot optimize the equation. “The best you can do is define a set of different scenarios and define what is optimal for each,” Tompkins said.

Then you need real-time visibility into what’s going on throughout the network so you can instantly pivot to whichever of the scenarios is taking place. It is a fundamental shift in the way supply chains are planned, Tompkins concluded.

- Emily Atkins is the editor of Inside Logistics magazine

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.