Why do lighting violations continue to be so prevalent?

Today’s lighting systems have never been better and the tools available to fleets and drivers to ensure they’re functioning properly have never been more advanced. There are telematics platforms that notify a driver and/or fleet manager in real-time when a light goes out. There are pre-trip inspection assistants available from truck makers that will cycle through the lights to simplify the inspection process.

And the lights themselves are now predominantly LEDs, built to last for many years. Heck, even those pesky high-mounted clearance lights on straight trucks and trailers that are so prone to damage by tree branches now come in a slimmer profile with more damage resistant lenses. So why does lighting continue to be the leading cause of roadside violations?

Kerri Wirachowsky, director of the roadside inspection program with the Commercial Vehicle Safety Alliance (CVSA) explains it in five words: “Drivers don’t do proper pre-trips.”

But unlike other components such as brakes and tires, which wear over time and usually provide some advance warning of a failure, lights can fail at any time. Even after a pre-trip inspection while en route to a delivery. And how the lights expire also varies by make and model. Some LEDs, for example, will fail one diode at a time, while others will lose clusters and some will go out entirely without warning.

As individual diodes fail, enforcement is left to rely on the eye test. “Until you can’t see the light from the distance required, you don’t have a violation,” Wirachowsky said of LEDs with failed individual diodes.

However, the outage of individual diodes should be recorded on the pre-trip inspection report and communicated to the shop for repairs, she added.

As for the excuse ‘That light was working just fine when I did my pre-trip,’ she said a light-out violation is still a light-out violation and an out-of-service truck or trailer is still out-of-service, even if it happens moments before a roadside inspection. But enforcement officers will sometimes give the operator the benefit of the doubt and not write a citation if their story is believable.

“A lot of times I didn’t cite the driver because I know a bulb can go out at any time,” Wirachowsky says. “If that light is all I have on that truck, I may not cite the driver but I’ll still put it out of service.”

A persistent problem

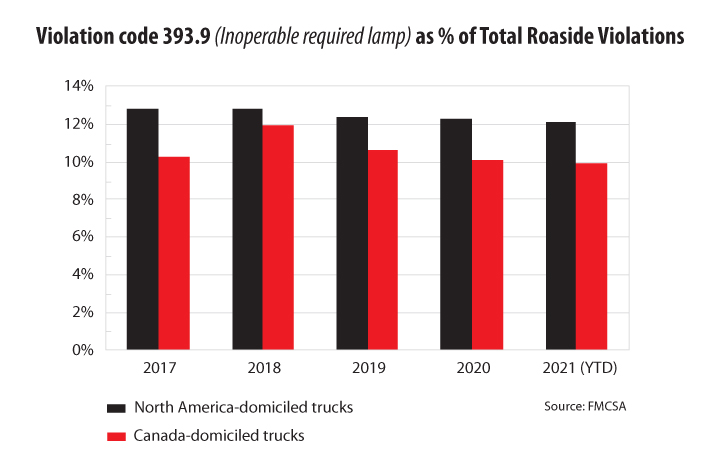

Lighting has been the leading cause of roadside violations for as far back as publicly searchable FMCSA inspection data goes. Specifically, ‘Inoperable required lamp (violation code 393.9)’ has been the leading culprit, regularly accounting for more than 12% of total roadside violations – more than twice the percentage of the next most frequent infraction. And during the CVSA’s Operation Roadcheck annual inspection blitz, lighting accounted for 13.5% and 15% of out-of-service (OOS) violations during the last two years, respectively. (Canadian fleets fared better, at 7.5% and 12.5%, respectively, but in both Canada and North America-wide, the OOS lighting violation rate increased this year).

More startlingly, one in four trailers on the road at any given time have a lighting violation, according to Ross Froat, vice-president of engineering and government affairs with Peterson Manufacturing.

“Not all LED lights are the same. There are multiple variables that contribute to the performance.”

Paul Sniegocki, Clarience Technologies

The first step fleets can take to get their lighting violations under control is to spec’ quality lamps and equally important, well designed wiring harnesses. Paul Sniegocki, executive vice-president – engineering and chief technology officer with Clarience Technologies, the parent company for Truck-Lite and Road Ready, says not all LED lights are created equal.

“Now, almost everything is LED lighting and the perception and assumption is LED lighting is somewhat of a lifetime light, because it’s solid state, there are no filaments and so forth,” he says. “The issue that arises is that not all LED lights are the same. There are multiple variables that contribute to the performance of the LED lights.”

Thermal management, corrosion resistance and shock resistance are a few variables that will fluctuate between designs on the market. And Froat warns the aftermarket is still rife with offshore products that haven’t been designed to, or tested to, North American standards. “Not all LED lights are the same, and there are environmental conditions that contribute to the failure of those lights,” adds Sniegocki.

He encourages fleets to get their lighting supplier involved during the truck or trailer spec’ing process, so the lighting manufacturer can work alongside the truck or trailer OEM on selecting the best lights and harness layouts for the vehicle.

“Fleets that involves us very early on in the process can take advantage of the field and application engineering expertise [available],” he says.

Once the best lights and wiring harness are selected for the application, ongoing maintenance is required. Froat feels this is overlooked by many fleets, especially when it comes to trailers.

“The FMCSA requires one annual inspection on all commercial vehicles, including trailers and dollies,” Froats says. “It’s a best practice to do it more than once a year.”

A thorough in-shop inspection can identify potential problems before they result in a light-out violation. And most lighting failures stem from the wiring harness and connection points rather than the lamps themselves, meaning it’s not as simple as a driver swapping out a lamp at roadside and continuing on with their delivery.

“The wiring harness on a 53-foot trailer is really large,” Froat points out. “And they get even bigger when you think about car carriers and other types of trailer equipment that’s out there.”

They’re not only long, they’re also exposed to some pretty harsh conditions.

“There has to be some recognition of the fact that some connections still require maintenance,” says Sniegocki. “The undercarriage of a trailer or a body is some of the most severe conditions over the road.”

Anti-icing chemicals and other materials put on the road during winter can eat away at connectors and even rocks and dirt can cause damage to the harness or knock loose braces and securing devices. Technicians working on these systems must follow proper guidelines in order to keep water or contaminants from entering the harness. Sticking a probe into a wire harness creates a pathway for contaminants to enter.

“Some of the more typical things we do not recommend is cutting and splicing into sealed harness systems,” Sneigocki says.

Froat encourages shop supervisors to get involved with the Technology and Maintenance Council of the American Trucking Associations, and to familiarize themselves and their technicians with the recommended practices developed there. “It really comes down to training,” he adds.

Technical assistance

While the trucking industry has not achieved a meaningful reduction in lighting violations, more help has arrived in the form of connectivity. At a time when seemingly everything on the vehicle is speaking to everything else on the vehicle, and in turn to the driver and fleet manager, light-out situations can be identified as they happen.

Peterson has had its PetersonPulse telematics system available since 2018.

“Smart trailer systems and smart tractor systems can notify you the instant a light isn’t working,” Froat says. “If the light was working when it was pre-trip inspected and now it isn’t, it gives you a chance to be alerted, pull off the road, and go to a repair shop or some area where you can fix it before getting a violation.”

Similarly, the Road Ready telematics platform offers light outage detection fleets can act on to reduce violations. It also helps streamline the troubleshooting process by indicating where the issue exists.

“We can identify where that failure mode is within the electrical circuits, so it saves a significant amount of time for the fleet itself,” says Sniegocki.

A light mounted to the corner of a body or trailer also notifies the driver immediately when a light goes out. From there, it’s up to them to tend to the issue right away. Before they find themselves at the scale with Wirachowsky, insisting ‘That light was working just fine when I did my pre-trip!’

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.

Never mind the clearance lights failures, how is it some get away with mounting off road use only lights on their bumpers or hood once the factory original light lenses are severely faded , and instead of replacing the original add them LED flood lights or bush light bars , and nobody seems to notice them blinding other drivers in the dead of night!?!?

Sometimes I see trailers at night without a single light showing. Either the plug isn’t grounded or they didn’t do an inspection at all. No excuse for not eventually seeing something is amiss.

Got dinged for no brake lights on a slushy day in November. Told the inspector I did a full pre-trip and they worked when I left. Together we walked around the unit, everything else was good. She went inside after telling me I was OOS which I knew and accepted. A roadside mechanic was there and he replaced the fuse.

Asked what the fine was and going to cost me and she told me she wasn’t going to issue me one. I asked if she believed I did the inspection and she said normally she won’t accept a verbal statement but said the trailer body is filthy but someone walked around that trailer because all the lights and the plate have been wiped clean. That was my proof, it sure saved my bacon that day.