Freightliner ready to produce eM2 electric truck, eyes vocational uses

Freightliner’s eM2 medium-duty electric truck has evolved from a rolling laboratory into a work-ready vehicle, with Daimler Truck announcing plans to begin series production this fall.

Building on the OEM’s established M2 106 truck platform, the Class 6 eM2 and its 194-kWh battery capacity will have a typical range of 180 miles (290 km), while the Class 7 with 291 kWh of power will travel up to 250 miles (400 km) on a full charge.

At launch, the trucks will come with 26-foot bodies including flatbeds, dry vans, and even refrigerated units, the latter of which will be supported by an ePTO available on Class 7 models. Penske was showcasing one of the refrigerated units at ACT Expo, complete with a Thermo King reefer.

“Utilizing the production experience from the eCascadia, the eM2 is the result of extension co-creation with our customers and years of real-world testing,” said Rakesh Aneja, vice-president and chief of eMobility at Daimler Truck North America.

Several lessons have been gleaned from the “innovation fleet” that placed pre-production models in customer hands. Even the source of motive power has changed. A proprietary Detroit ePowertrain and Detroit eAxles replace components from third-party suppliers such as Meritor, and batteries will be managed the same way as those found in the truck’s Class 8 sibling.

Innovation Fleet lessons

Similar batteries, axles, and high-voltage components will all play a role in refining the ultimate production processes.

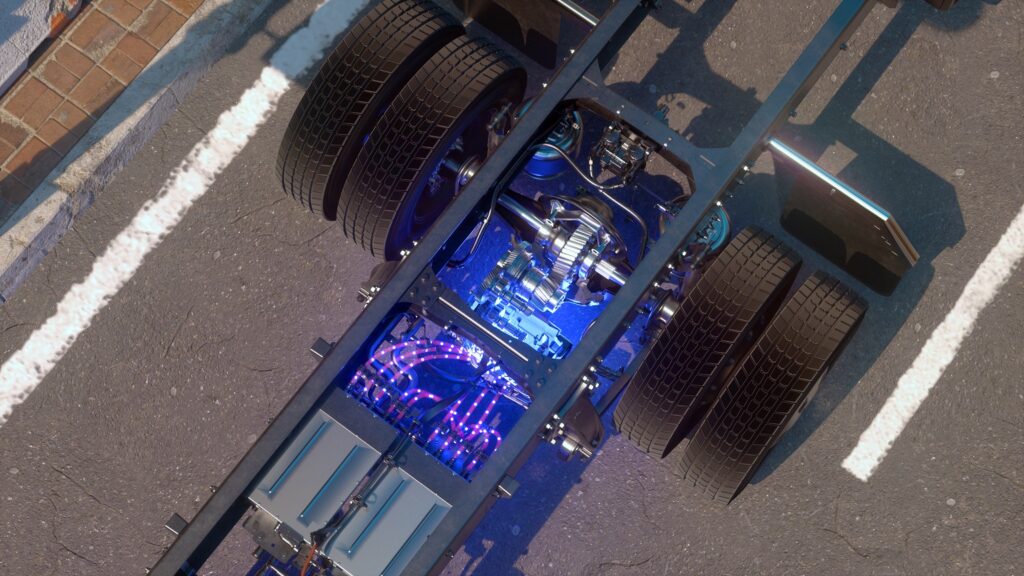

Integrating the motor in the axle rather than using a central location, the OEM was able to eliminate the traditional driveline, added Katie Rabideau, eMobility product marketing manager, during a media event. “We’re also optimizing weight and space by integrating it with the axle, versus consuming precious space where the batteries are currently.”

“By locating the motor on the center of the axle, we can use industry-standard wheel ends, so braking systems, the wheels, the tires, all can be shared with what we are spec’ing on our diesel vehicles,” she said.

Even the hood and grille have been updated, both to enhance aerodynamics and offer the styling that signals the eM2 is part of the eCascadia portfolio.

The updates don’t end there. Changes to the HVAC system help better address defrosting needs, air and refrigerant compressors have been replaced, and a single button on the dash offers a central location to lock out the power. That dash also includes a fully customizable information display, and a touchscreen mounted on the B-panel for infotainment, navigation, and charging insights.

Underneath, the batteries are shielded by side-impact guards, but that’s not the only feature included in the name of safety. A Detroit Assurance suite of safety systems includes Active Brake Assist 5.0, tailgate warnings, adaptive cruise control, lane departure warnings, and intelligent high beams.

New eServices available through Detroit Connect deliver charging information and other data about vehicle health, giving fleet managers the tools to plan routes that reflect predicted range and monitor the state of charge for multiple units.

Future electric vocational trucks

The electrification journey doesn’t end here.

Daimler is also launching a vocational innovation program to explore options in utility, sweeper, dump, towing and refuse segments. Pre-production versions of those vehicles feature up to 330 kWh of battery capacity, targeting a range of 150 miles (240 km).

Range will only be part of the equation, of course. Many utility vehicles travel only a few miles to a job site, where a boom would be extended and sit in place for an extended period of time. In contrast, batteries might be depleted more quickly by a tree service that continually needs to reposition such a boom. Another eM2 on display was outfitted as a sweeper by Hexagon Purus and Alamo Group. While that would run for an extended period, it might typically roll along at less than 25 km/h.

It’s all about finding the right balance between applications, collective power needs, and the specific tools for a job.

“Very rarely does Freightliner or DTNA build a truck in the vocational space that we don’t have to partner with someone else that puts equipment on the back of that truck,” noted Brian Daniels, vice-president — vocational national accounts.

“Packaging is a big deal for vocational,” Aneja added, referring to the lessons that will need to be learned through the program. If batteries are mounted too far back on such a truck, for example, there would be limits to where an upfitter could mount a crane’s pedestal.

“The team came up with a very unique packaging design, for example, where it’s trying to leverage space underneath the frame rail – so that we can package our batteries effectively. And the back-of-cab protrusion, which is a very significant metric, is only 10 inches.”

The shorter that distance, the more room remains to mount equipment. On one of the first models developed with Altec – complete with a 55E bucket — this left enough room for outriggers to deploy close to the truck cab.

Beyond the packaging needs

But vocational-related needs won’t end with the packaging. Unique controls on the same truck, for example, included a three-light system to inform workers in the bucket about the truck’s state of charge.

“It’s not just packaging, but it’s optional content, it’s all those things,” said Michael Stark, electric vehicle program manager. “We’re taking about 80 years’ worth of internal combustion engine development and option content and all those things, and trying to get there relatively fast in the electric vehicle space.”

“Our vision is leading sustainable transportation by moving at the speed of right, because right is the only way to go forward,” Aneja said, referring to Daimler Truck’s goal of offering only CO2-neutral vehicles in Europe, North America and Japan by 2039.

“It’s doing the right things, it’s doing them at the right time, in the right way, and for the right reasons.”

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.