Navistar says S13 Integrated will be its best, and last, internal combustion powertrain

It’ll be the last internal combustion engine Navistar will ever design from the ground up. And, officials said assuredly during a major reveal of the S13 Integrated powertrain at Las Vegas Motor Speedway, it will also be its best ever.

Navistar took the wraps off the first integrated global powertrain designed with new parent company Traton Group on Tuesday. And president and CEO Mathias Carlbaum noted it’s the biggest project the OEM has undertaken in more than 50 years, developed over five years in a close partnership with Traton’s Swedish Scania brand and optimized for use in North America.

Goran Nyberg, Navistar’s executive vice-president – commercial operations, said the new powertrain — when combined with aerodynamic enhancements to the International LT — will provide a 15% fuel economy improvement over the LT and first-generation A26 engine, which was launched just five years ago.

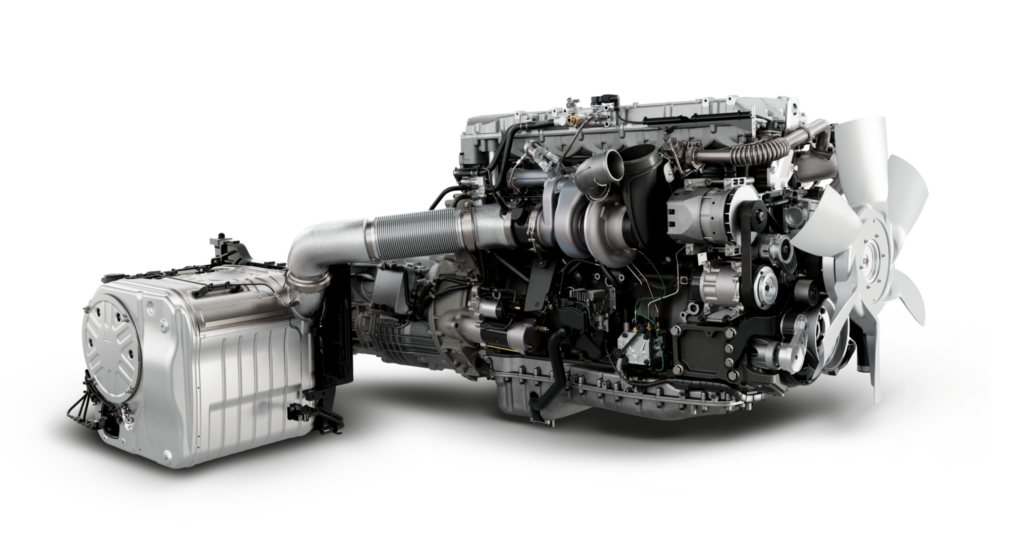

The powertrain also features a new T14 14-speed automated manual transmission and redesigned dual-stage, one-box exhaust aftertreatment system. They were developed using a modular design system perfected over the years by Scania.

It’s not electric, but Carlbaum said the new S13 Integrated marks an important “milestone” on the truck maker’s journey to zero emissions. By 2030, Navistar projects that 50% of its new vehicle sales will be zero-emission models, expanding to 100% by 2040. That leaves lots of diesel-powered trucks to build over the next 18 years.

“Here we are today, launching an internal combustion engine,” he said. “There is no conflict in that. On the contrary, internal combustion engines will be required for many years until the electric vehicle can be fully adopted and when we have available cross-country infrastructure in place.”

Carlbaum said the fuel economy and aerodynamic improvements mark “the greatest leap toward carbon-neutral transport ever made by our company,” adding, “certainly this powertrain is the most efficient we’ve ever developed.”

Global collaboration

Volkswagen took an initial 17% ownership position in Navistar about six years ago before spinning off the truck business as Traton Group and buying the remaining 83%. But almost immediately after taking its initial stake, engineers from both companies were working side by side to develop the S13 Integrated engine. This meant adopting a modular design approach that would serve all global members of the Traton Group.

“Think about it as Lego,” Carlbaum said of this modular design philosophy. “All the interfaces are common. It enables more options with fewer parts. The S13 Integrated is the start of that commonality, that modular thinking that we’ll bring into Navistar in the years to come.”

An example of how Navistar engineers contributed to the design is the inclusion of front and rear power-take-off options, something that’s not common in Europe with its cabover trucks. “We will have front engine power-take-off availability when we have this in vocational models because of the importance of the North American marketplace,” said David Hillman, director of integrated powertrain marketing.

New approach to emissions

The S13 takes a new approach to emissions control. While it still employs exhaust gas recirculation, a new clean burn combustion cycle has been designed to greatly reduce the EGR levels required.

As a result, the S13 doesn’t require an EGR cooler, the source of costly repairs (replacement costs are about US$4,000). Also eliminated is the variable geometry turbocharger (replacement cost US$2,000), replaced by a simpler fixed geometry turbo. Active diesel particulate filter (DPF) regenerations (and associated fuel dosing) are no longer required and DPF service intervals have been extended. If the truck achieves 8.2 mpg (28.68 L/100 km), the cleaning interval will be stretched to 650,000 miles (more than 1 million km) – or an entire lifecycle if a fleet replaces its trucks in five years or less.

Reducing EGR results in higher NOx formation. That NOx is reduced by a new two-stage, one-box aftertreatment device with diesel exhaust fluid dosed aft the turbo, with the second dose occurring as the gas enters the aftertreatment device itself.

“We don’t see much soot load in the aftertreatment device,” Hillman said of the new design.

‘Advantage of coming late’

The powertrain, thanks largely to the removal of the EGR cooler, loses about 30 to 52 lb. compared to the current A26 with Eaton Endurant transmission and Cummins aftertreatment system.

Michael Grahe, executive vice-president – operations, said the company’s approach to exhaust aftertreatment came from seeing the pain points fleets were experiencing with engines currently in the market.

“We had, with this powertrain, the advantage of coming late,” he said in an interview with TruckNews.com. “Everybody else launched their engines already, so we could study what they’ve been doing.”

North American engine makers first employed EGR to eliminate particulates, followed several years later by supplemental SCR to reduce NOx, meeting phased-in regulatory requirements.

“So, they developed an [EGR] engine and then put SCR on it later,” explained Grahe. “We designed from the ground up knowing we were going to use SCR, so we can play with the different levers you can pull, avoid the soot, avoid the EGR cooler and have this dealt with by the SCR system. That’s the advantage of being late in this race.”

Other notable changes in the S13 compared to the A26 include a higher compression ratio of 23:1, compared to the 20.5:1 compression ratio seen in the current engine. The high-pressure fuel pump runs at 28% reduced pressure thanks to the revised combustion strategy, so less energy is required by the fuel pump and can be redirected into powering the vehicle. A cast aluminum cam cover and oil pan are standard to reduce corrosion.

A new transmission

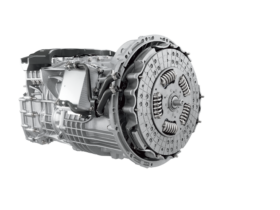

The new T14 automated manual transmission was also designed from a clean sheet. It’s an overdrive design that can run in direct drive in 13th gear, where it is at its most efficient and will run most of the time when spec’d with the most efficient power ratings. (All power ratings available with the A26 have been retained).

It boasts an unlimited gross combination weight rating, and features planetary gears for a more compact design and higher-speed reverse gears. The T14 also has shorter steps than competitive models, for quicker acceleration.

An electronic clutch actuator also contributes to quick, smooth shifting. “It does not consume air during high back and forth maneuvers,” Hillman said of one benefit.

Components are precision lubricated for reliability and protection from any moisture that’s entered the system. A heat exchanger quickly warms up the internal temperature in cold weather for smoother shifting on start-up, and keeps the transmission oil cooler in hot temperatures.

LT updated

The S13 Integrated powertrain will first go into the International LT on-highway truck and RH regional hauler. Medium-duty International trucks will be powered by Cummins engines. The LT got some aerodynamic upgrades to complement the fuel savings the powertrain itself delivers.

The new aero package includes: DEF and fuel fill close-outs; steering wheel close-outs and a modified lower skirt; and a new roof extender. The updates improve airflow around and underneath the chassis, and between the tractor and trailer gap.

The front end receives a new bumper and grille style, and the sleeper cab now features a nine-inch mattress and flip-up bunk for additional space and improved comfort. An electronic parking brake is now standard, and will automatically engage if a driver forgets to set it.

Customers seeking a 15-liter option over the S13 Integrated with its 12.7 liters of displacement, will still be able to get it. But Grahe questions the need.

“Why do you need a 15-liter?” he asked. “Is it really something you need or is it because you’re used to a 15-liter and emotionally attached. There’s probably a difference in residual value because the market is used to it. But the performance level for a 13-liter is an obvious advantage when it comes to fuel consumption and weight. We are seeing a lot of bigger fleets already in North America acknowledging this and shifting to 13-liter [powertrains].”

A European version of the S13 Integrated was launched in Scania trucks in Europe last year. Here in North America, it is slated to enter production next summer and is currently undergoing validation testing in cold weather (-40 Celsius in Alaska), hot weather (+43 Celsius in Arizona), and at altitude (in Colorado). By the time it enters production next summer it will have received more than 4 million miles (6.4 million km) of on-road testing and 300,000 dyno validation hours, the company said.

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.

Coupling the entire powertrain together, it is a slight weight savings over the A26/Eaton endurant current setup. Warranty will be extended to 60 months I’m told.

i find the info you have provided very interesting, will this decrease the actual weight of the unit. Warranty increased to 60 months or 1,000,000 kms