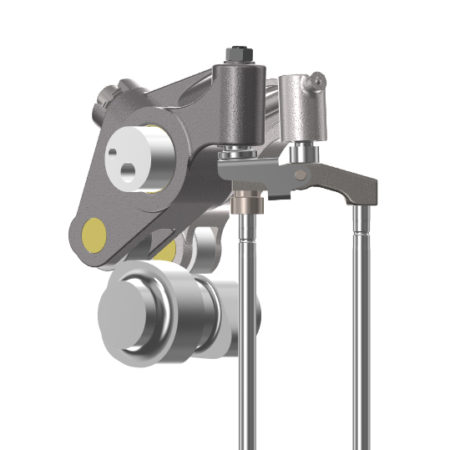

Jacobs Fulcrum Bridge eliminates lash adjustment need

Jacobs Vehicle System’s new Fulcrum Bridge for off-highway trucks will eliminate the need to periodically adjust engine lash – the mechanical clearance between the valve and camshaft.

It will also make conventional engine braking compatible with the lashless technology that’s widely used by heavy-duty engines in off-highway applications.

The Fulcrum Bridge employs Hydraulic Lash Adjusters (HLA), which allow for consistent valve motions through all operating conditions, Jacobs says. The end result promises to enhance engine performance and fuel economy.

The Fulcrum Bridge employs Hydraulic Lash Adjusters (HLA), which allow for consistent valve motions through all operating conditions, Jacobs says. The end result promises to enhance engine performance and fuel economy.

It means engine manufacturers will be able to eliminate bottlenecks caused when setting the lash on engine assembly lines. Engine operators, meanwhile, eliminate the need to check and adjust lash for intake and exhaust main events. The latter benefit is especially important in specialty off-highway applications because clean surroundings are needed when accessing the overhead and opening the valve cover.

Not only that, manual lash adjustments are often slightly inaccurate. A shift of no more than 0.01 cm from an optimal setting could affect engine breathing and efficiency, Jacobs says.

Conventional engine brakes are not traditionally compatible with HLAs because, when the engine brake holds open an exhaust valve, the HLA will over-extend – possibly allowing the valve to contact the piston when the engine brake is turned off. Jacobs prevents the over-extension by applying a reactive load to the HLA during engine braking.

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.