Understand torque, hp, and axle ratios

TORONTO, Ont. — Horsepower always gets top billing in engine ratings, but it’s torque that does most of the heavy lifting in today’s powertrain. Here’s what the numbers mean, how they relate, and how they affect performance:

Torque is a measure of the rotational force applied to the engine’s crankshaft and ultimately to the drive wheels. Torque is expressed in pound-feet (lb-ft). Horsepower is a measure of the amount of work the engine does over time, expressed as X horsepower at a given engine rpm (445 hp @ 1,600 rpm).

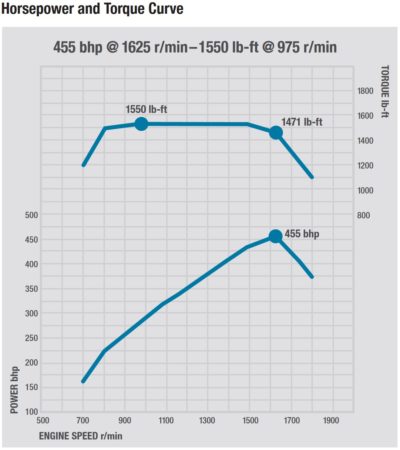

In very unscientific terms, torque is “pulling power”, while horsepower is what keeps the truck moving at a given speed. As you can see from the torque and horsepower chart, engine torque is highest at low engine speed (1,550 lb-ft @ 975 rpm), while horsepower is highest at higher engine speed (455 hp @ 1,625 rpm).

The axle ratio defines the number of times the input shaft (driveshaft) will have to to produce one full rotation of the axle shaft. For example, a 4.11:1 ratio means the driveshaft will have to rotate 4.11 times to produce one full turn of the axle. Likewise, a 2.24:1 axle ratio means the driveshaft rotates 2.24 times for every one rotation of the axle.

For fuel efficiency, a low numeric drive axle ratio (2.24:1) gives you a low engine rpm (where all the torque lives) at cruise speed, thus reducing fuel consumption. A higher numeric axle ratio (4.11:1) keeps the engine running in the higher horsepower range, thus improving performance.

If fuel efficiency is your goal, you’ll want an engine that produces a lot of torque at low rpm (1,100-1,200 rpm). Provided the weight and terrain are suitable, the dealer might recommend what is called a “downsped” driveline (gear fast, run slow) with low numeric axle ratio, like 2.47:1 or 2.26:1. If high performance is your preference (high weight and/or hilly terrain), a higher numeric axle ratio will be more suitable to keep the engine in the higher horsepower range of 1,300-1,400 rpm (3.36:1 or 3:55:1).

Have your say

This is a moderated forum. Comments will no longer be published unless they are accompanied by a first and last name and a verifiable email address. (Today's Trucking will not publish or share the email address.) Profane language and content deemed to be libelous, racist, or threatening in nature will not be published under any circumstances.

I decided to try to make an electric truck from an old one. Still in the learning curve on Induction and SynRM electric motors. At some point I saw something about rear axles breaking from high torque shear force.

My plan was to connect the motor shaft directly to the rear axle input shaft plate.

There must be a way to calculate and adjust the torque through some sort of a frequency controller in the motor’s power supply.

Since electric motors are instant high torque which would apply high torque with the mass of the truck stationary and that could easily shear the ring and worm gear.

Is there a way to know what that shear force limit is for any given rear axle?

Please Sir tell me that how much horsepower has 1. 2-axle truck, 2. 3-axle truck, 3. 4-axle truck, 4. 5-axle truck 5. 6-axle truck

Thank You for the Info. In your opinion, pulling a Reefer, 500 hp Cummins, 1850 Torque, what is the best gear ratio for fuel without being a slow truck. Plse Advise.

Excellent… excellent explanation and presentation of torque,HP and gear ratio.

201 hp 236 lb-ft of torque to 5.30 axle ratio. good setup?

I want to simulate in a 3D animation a semi-truck such as in your article pulling one trailer with its maximum load. I still learning how engine rpm, wheel rpm and torque, road speed and gear ratios work together to get a rig moving so I need some help. Perhaps there is some site, Excel file or detailed explanation somewhere.

This is so that I can program the truck to be realistic as it moves from stop to maximum road speed. I need to move through the gears (18 gears). I want to vary the engine power, the payload and/or add trailers (so overall load can vary).

Thank you for any help. I have been collecting lots of info, but I am not sure whether I have all that I need.