maintenance

Deep Trouble: Repairing trucks and trailers after a flood

TORONTO, Ont. -- Water isn't kind to electronics or brakes or air systems or engines. The last thing short of a fire you could want to happen to your truck is to have it submerged in flood. Actually, a fire might be preferable -- the damage is obvious, and you'll get less argument from the insurance company about replacing it.

Video: CVSA Inspections Episode 15: Under the Truck

The Commercial Vehicle Safety Alliance’s (CVSA) International Roadcheck scheduled for June 5-7 2018, starts tomorrow! With that in mind we take a look back at this 2017 video series with Today’s Trucking editor John G. Smith and Samantha Sarasin, Ontario Ministry of Transportation enforcement officer and provincial Commercial Vehicle Safety Alliance (CVSA) instructor who explain every step in a CVSA inspection.ion In this episode we look at all things under the truck.

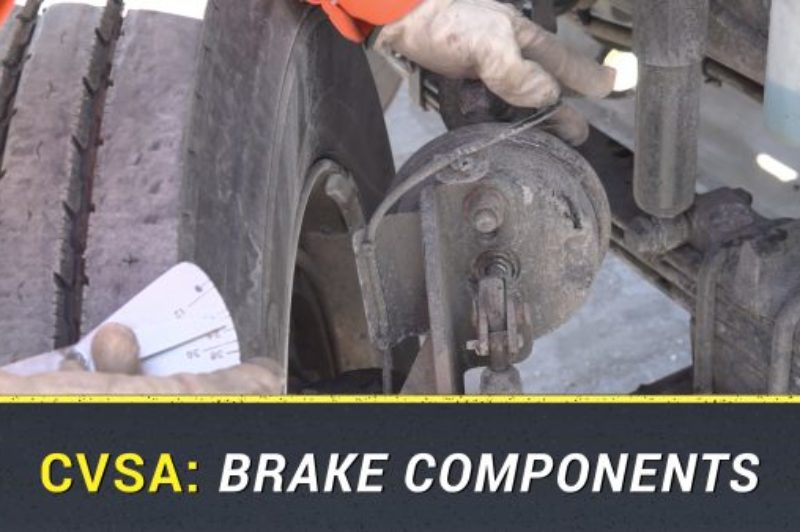

Video: CVSA Inspections Episode 14: Brake Components

We’re less than a month away from the Commercial Vehicle Safety Alliance’s (CVSA) International Roadcheck sceduled for June 5-7 2018. With that in mind we take a look back at this 2017 video series with Today’s Trucking editor John G. Smith and Samantha Sarasin, Ontario Ministry of Transportation enforcement officer and provincial Commercial Vehicle Safety Alliance (CVSA) instructor who explain every step in a CVSA inspection. In this episode we look at brake components.

Video: CVSA Inspections Episode 4: First Things First

We’re less than a month away from the Commercial Vehicle Safety Alliance’s (CVSA) International Roadcheck sceduled for June 5-7 2018. With that in mind we take a look back at this 2017 video series with Today’s Trucking editor John G. Smith and Samantha Sarasin, Ontario Ministry of Transportation enforcement officer and provincial Commercial Vehicle Safety Alliance (CVSA) instructor who explain every step in a CVSA inspection.

Gear up for April 18 maintenance summit

TORONTO, Ont. – The Canadian Fleet Maintenance Summit is fast approaching and will bring high-profile industry speakers from across North America to Toronto's International Centre on April 18. And there will be plenty to absorb, from electrification, to collision mitigation, spec'ing practices, fuel economy, and more.

Parts is Parts? Hardly. Observations from Heavy Duty Aftermarket Week.

LAS VEGAS, NV -- Children of the 1980s might recall a Wendy’s commercial that mocked the quality of chicken sandwiches from competing fast food chains. “Parts is parts,” the cashier for a generic restaurant says with a shrug, suggesting different pieces can be fused together into some sort of processed Frankenchicken. There are clearly differences in parts, though.

Time is the key to profitability

MISSISSAUGA, ON - Maximizing profitability in an industry where margins can be thin comes down to just one thing: time. Panelists at the Surface Transportation Summit had differing views about where fleets could make the best use of their time to convert it into dollars and cents, but both agreed that the old adage is true: time is money. "Time in trucking is a perishable commodity," said Brian Abel, a freight network engineer for KSM Transport Advisors. Abel and fellow panelist Mike Buck, president of MCB Management Consulting, spoke about different ways fleets could save time by being proactive and rooting out waste. Buck presented ways fleets could capitalize on being proactive about maintenance, creating a schedule that would mean less downtime, would control costs, and would maximize the efficiency of equipment.

Rent a Wrench: deciding what to outsource

Maintenance is a fact of life whether it involves a preventive oil change or roadside repair. But the question of whether the work should be completed in a fleet shop or by a subcontractor will be a matter of careful number crunching and personal preference.