axles

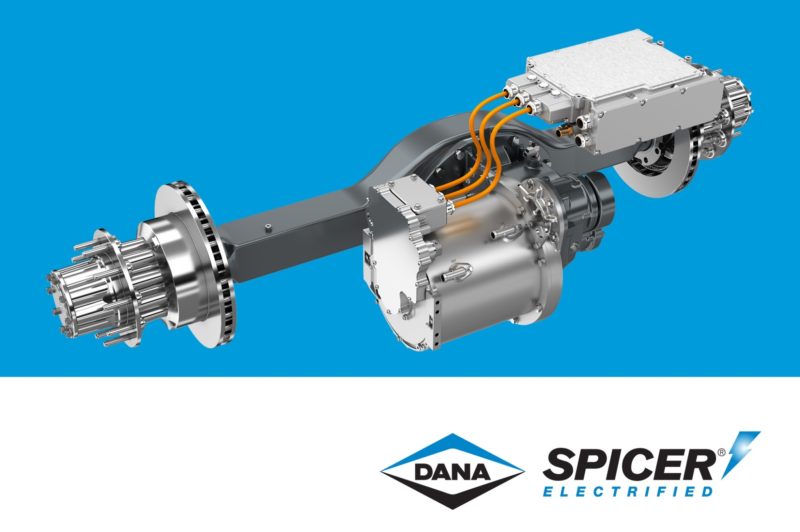

Driving Force: Axles are at the heart of an electric revolution

TORONTO, Ont. -- We're at the dawn of a new era in the propulsion of heavy trucks. Electric powertrains are opening new packaging and integration possibilities, including driven axles. Traditional transmissions, driveshafts, power dividers or differentials are no longer required.

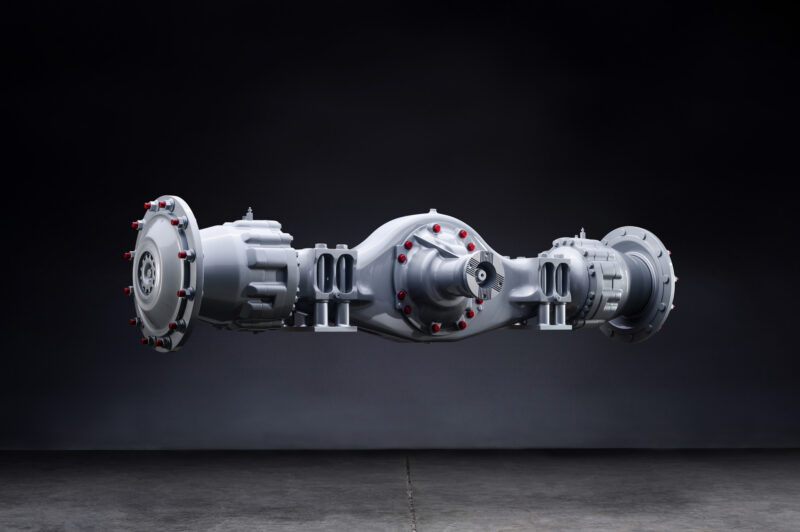

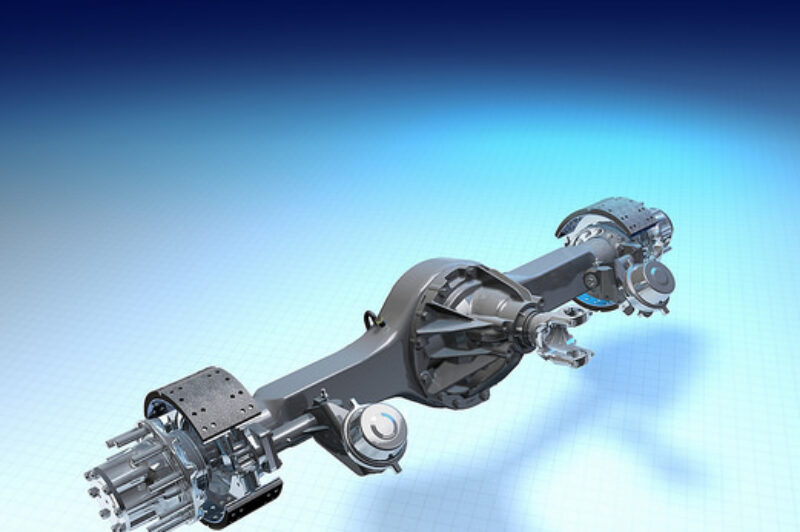

Dana’s Dual Range Disconnect

First revealed at the Mid-America Trucking Show in March, Dana's Dual Range Disconnect drive axle system offers the fuel savings benefit of a downsped 6x2 drivetrain and the performance benefits of conventional 6x4 setup with a mid-range axle ratio. The key word here is disconnect. While running at speeds up to about 54 mph, the system functions as a 6x4 with torque going to all four wheels for optimum traction. It also runs at a 3.10:1 ratio for better performance and startability. Above 54 mph, the interaxle driveshaft disengages, leaving the driving to only the forward drive axle. Interestingly, the axle ratio of the forward axle is 2.26:1, which lowers engine rpm and in effect creates a downsped drive train. The benefit, of course, is better fuel economy resulting from a 300-400 rpm drop in engine speed.

Volvo’s Adaptive Gearing

Volvo Trucks has put a new spin on an old powertrain management strategy; by locking out top gear on its I-Shift overdrive transmission, drivers can pull loads efficiently in 11th gear (direct drive) and still get the performance they want. When running empty, sensors in the transmission and the suspension sense the lower weight and unlock 12th gear, which is overdrive. The truck can cruise home in at a very low engine speed at a higher road speed. This video explains how Adaptive Gearing works and features more excerpts from an interview with Gene Brice, co-owner of Idaho Milk Transport. Adaptive Gearing is ideally suited to tank fleets that run about half their miles empty, and when you hear Brice's fuel economy with this system, you'll be asking if it can work for you too. And don't forget to check out our Focus On report on Volvo's Adaptive Loading system to see what it has to offer.

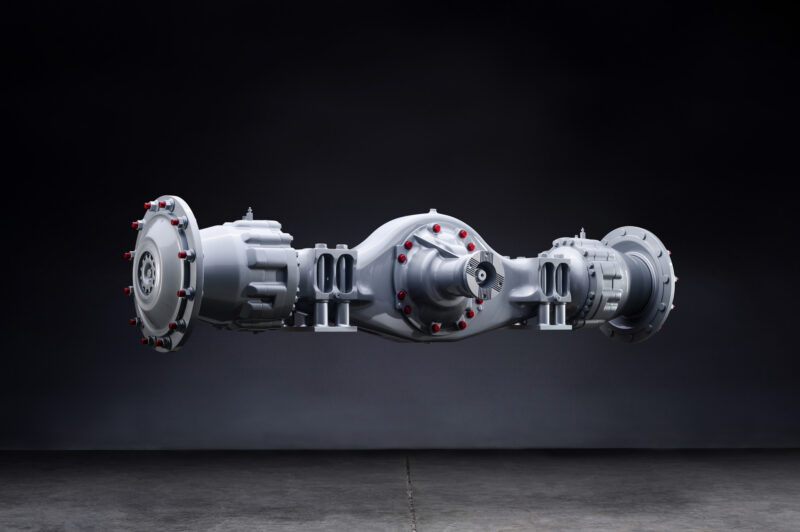

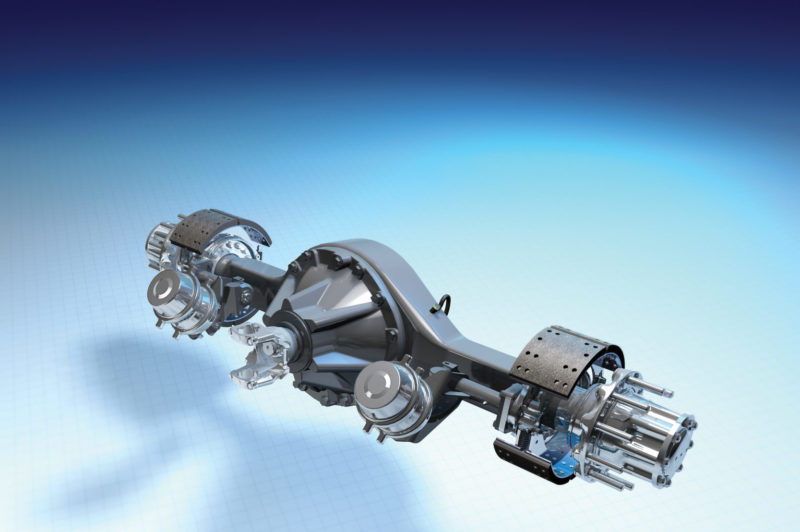

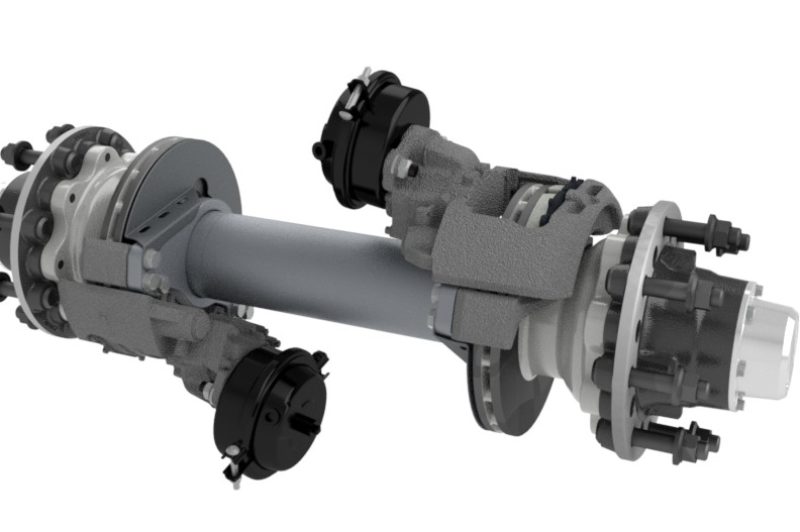

Mack Celebrates New Axle Production Line

HAGERSTOWN, MD -- Mack Trucks this week inaugurated its new axle line at its Hagerstown, MD facility, with a look to its past. The new line, where Mack powertrain components have been assembled since 1961, is part of a US$30 million investment, which brought assembly of all Mack heavy-duty drive axles and machining of Mack carrier housings to the plant.